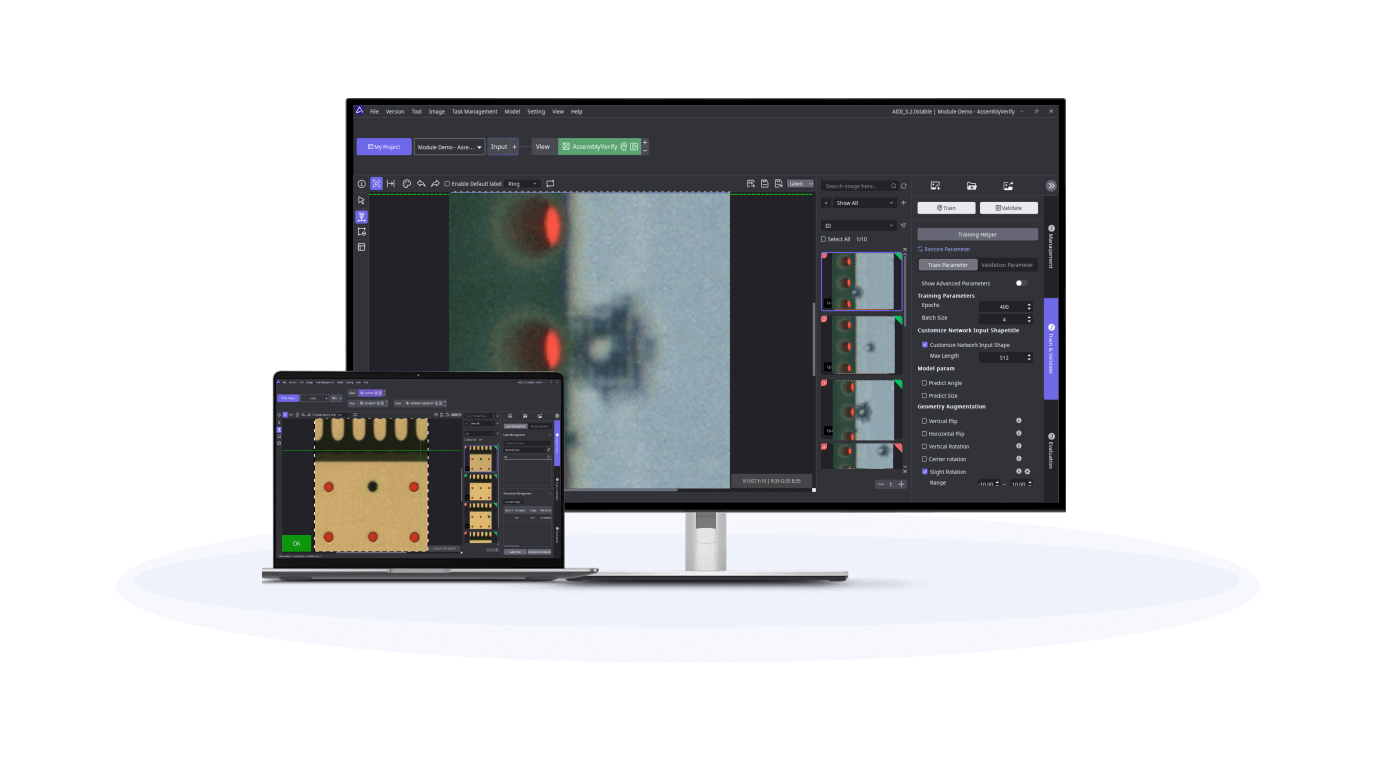

Industrial-grade AI algorithm development tool, focusing on the entire process of industrial AI vision algorithm development

Industrial AI Vision Algorithm Platform Software - AIDI

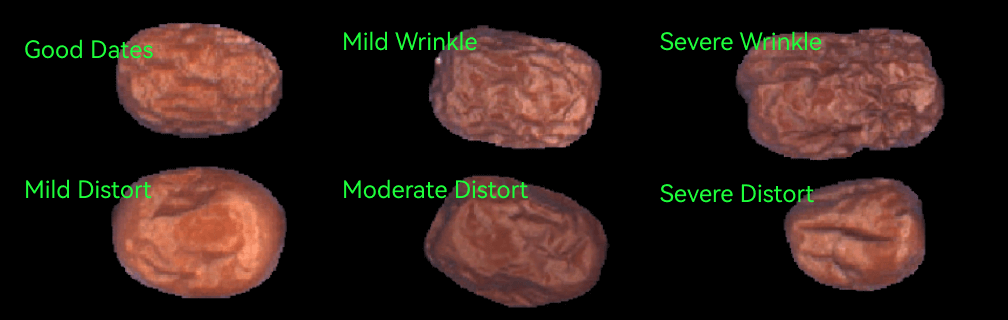

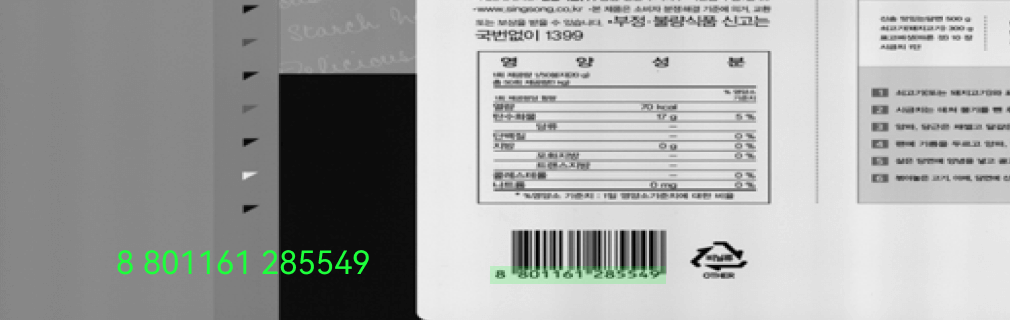

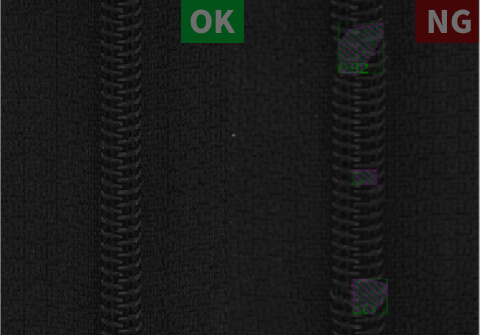

AIDI is a professional-grade industrial AI vision algorithm platform software developed by Aqrose Technology for industrial vision applications. Built on deep learning, it incorporates 8 core AI functions to tackle challenges such as complex defect localization, detection, classification, and character recognition, delivering exceptional detection capabilities. With over 1,000 factories already using the platform and more than 10,000 standard industrial AI vision software deployments, AIDI serves a wide range of industries, including consumer electronics, semiconductors, power batteries, food, agricultural products, and packaging, spanning 50+ specialized sectors

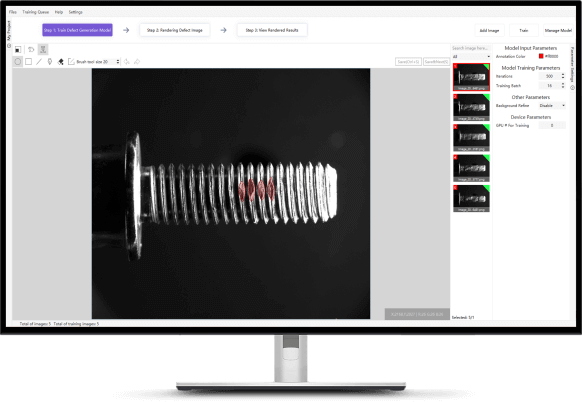

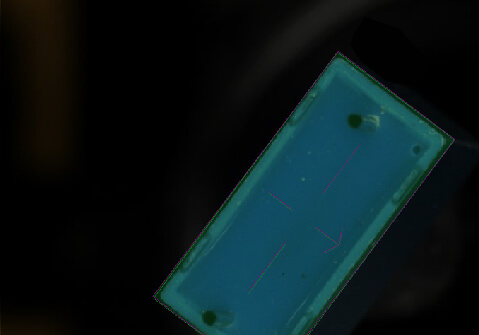

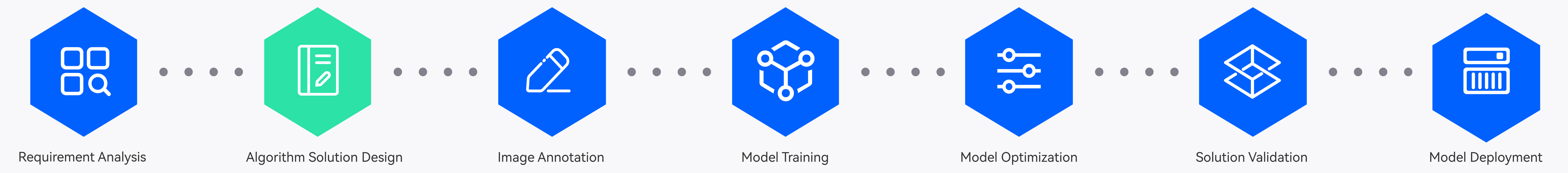

Designed specifically for industrial AI vision algorithms, it covers the entire process, including algorithm solution design, image annotation, model training, model optimization, solution validation, and model deployment

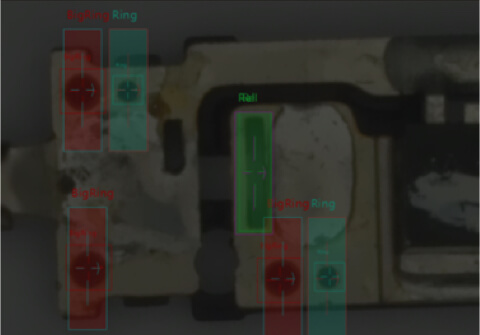

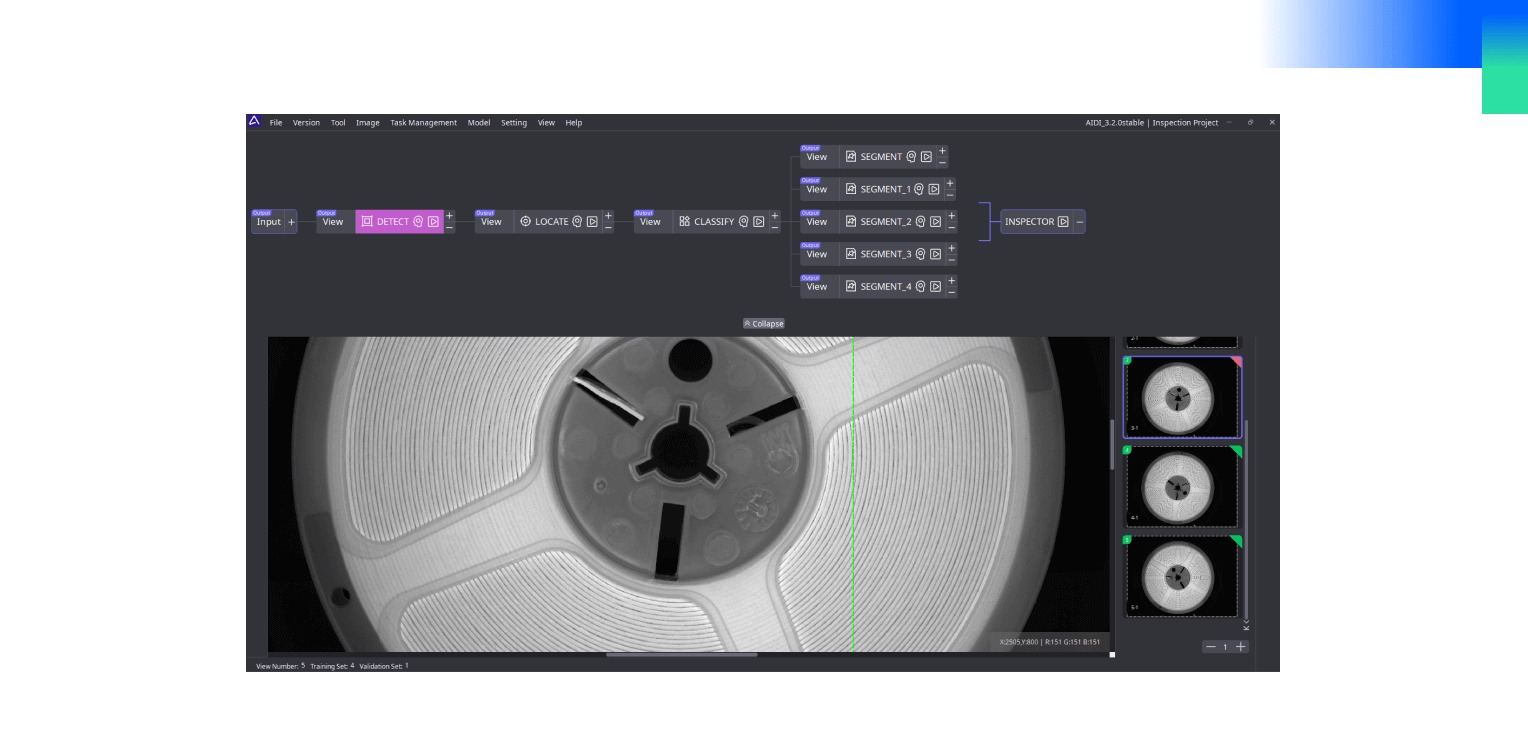

- Industrial vision detection scenarios often involve high algorithmic complexity, typically requiring multiple algorithms and models. Traditionally, this necessitates external code or software to establish logical connections between AI models, manually transferring image sets. A process that is complex, laborious and a challenge to holistic management. AIDI simplifies this process with its graphical algorithm workflow orchestration tool: Algorithm Canvas. This intuitive tool allows users to design the entire algorithm process, from image input to result output, in a visual workflow, significantly reducing the complexity of algorithm development.

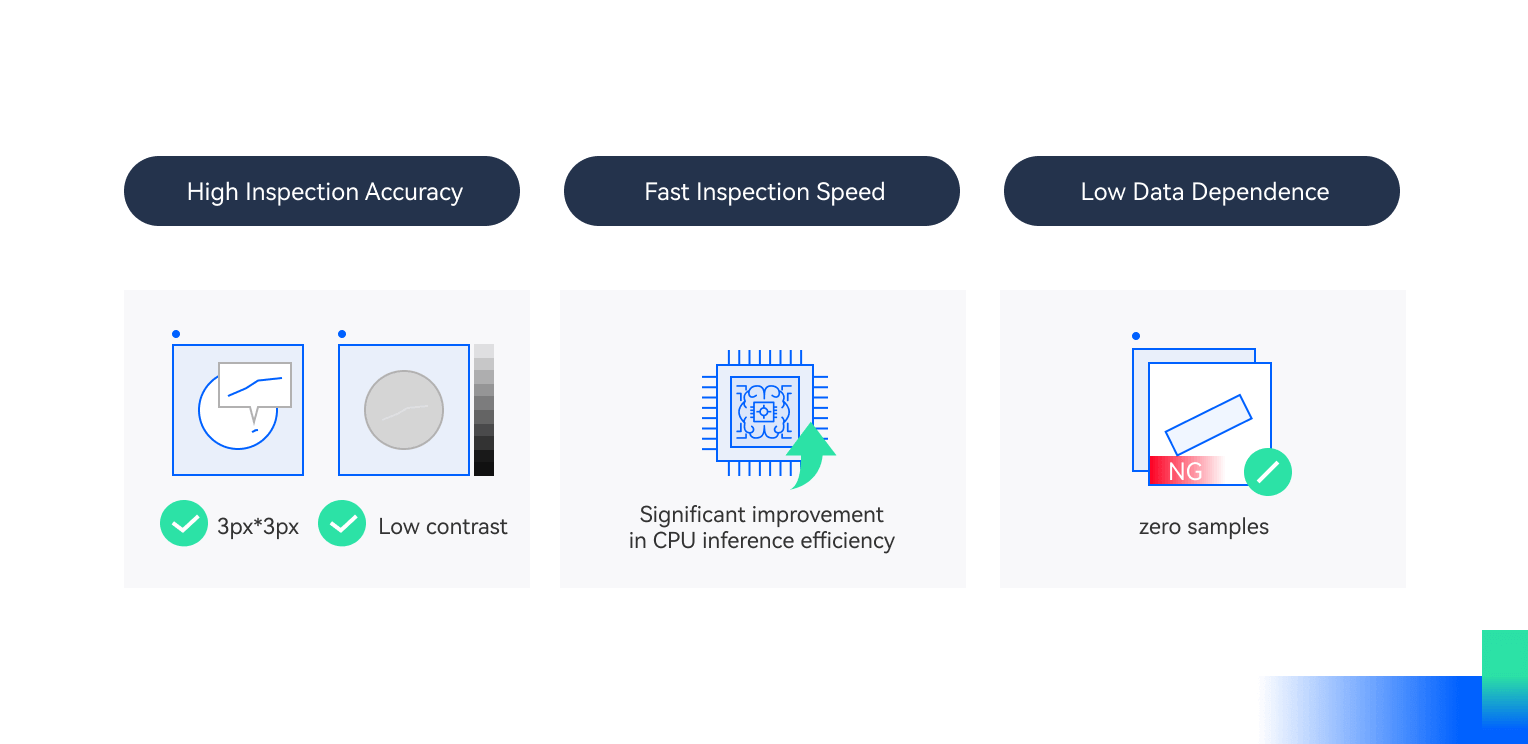

- An efficient and lightweight network structure designed for industrial scenarios, meeting the high-speed inspection requirements.

GPU inference achieves exceptional speed, processing 5-megapixel images in under 20ms per image.

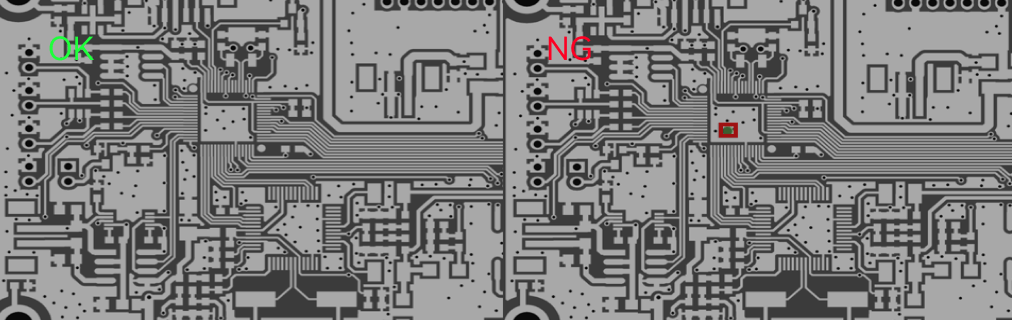

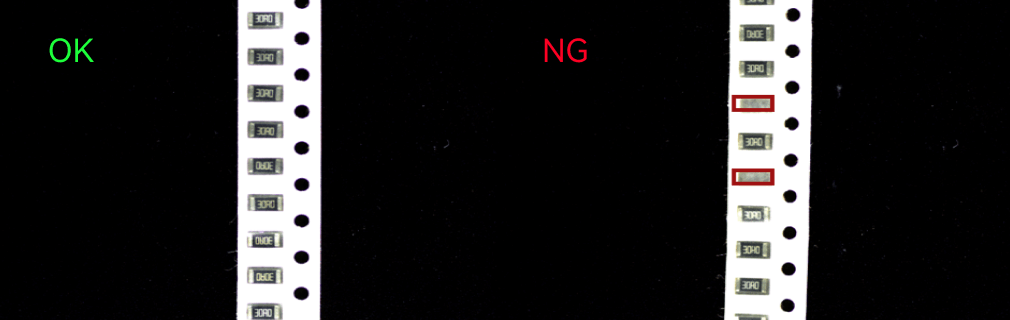

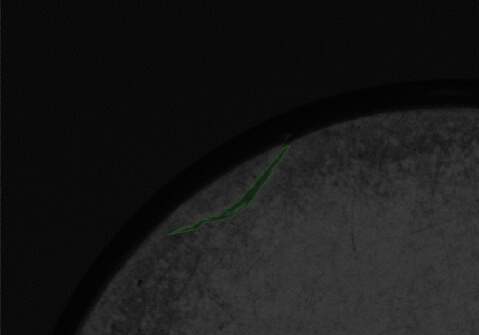

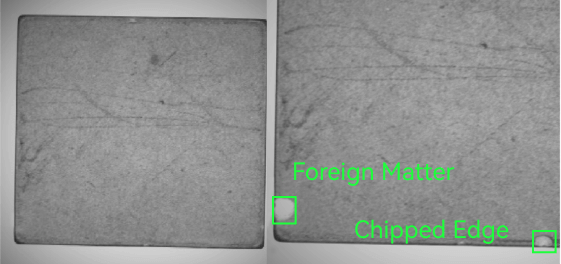

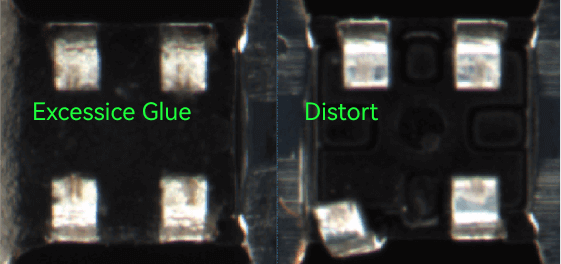

CPU inference significantly improves efficiency, processing 5-megapixel images in approximately 50ms per image, eliminating GPU costs in medium-to-low-speed scenarios. - Accurately detect small and complex defects, capable of detecting defects as small as 3x3 pixels with a contrast level of 10DN.

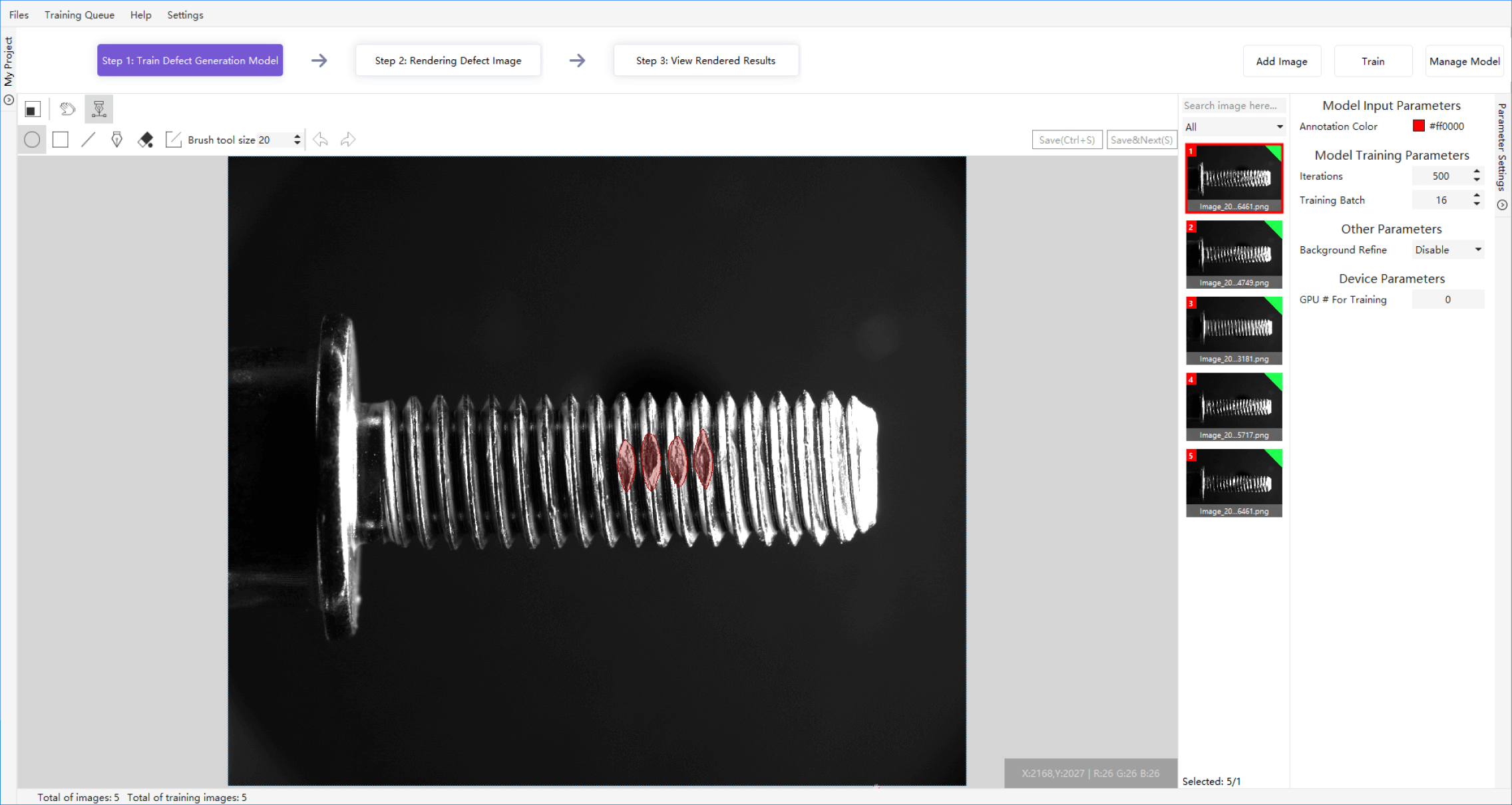

- Fully supports small-sample learning technology, requiring only 20-30 images per defect type for stable modeling. Advanced good-product learning capabilities enable defect detection by identifying common features, achieving zero-sample modeling in some scenarios.

- The "training recommendation set" feature can recommend suitable datasets to users based on factors such as previous success cases, dataset coverage, diversity, or the complexity of specific problems, according to the specific application scenario or needs. Users no longer need to manually analyze data features one by one; with a simple click, the system will intelligently select and recommend training images.

- Incremental training is supported, allowing the model to learn only what is added as new data arrives, rather than having to train from scratch each time. Only learning what is added helps the model adapt quickly to new situations and significantly reduces model iteration time.

- Multi-dimensional training sample management function is provided to ensure the balanced distribution of defective training samples in all dimensions. Equipped with a variety of defect label screening methods, users can orderly manage multiple categories of defect labels to adjust the sample set and improve the training effect.

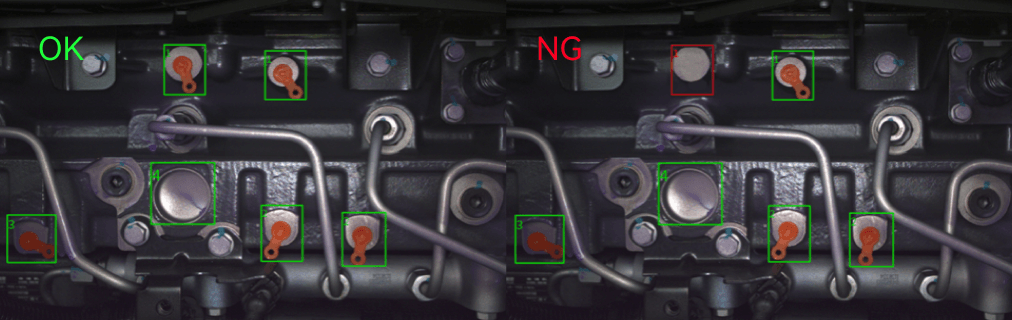

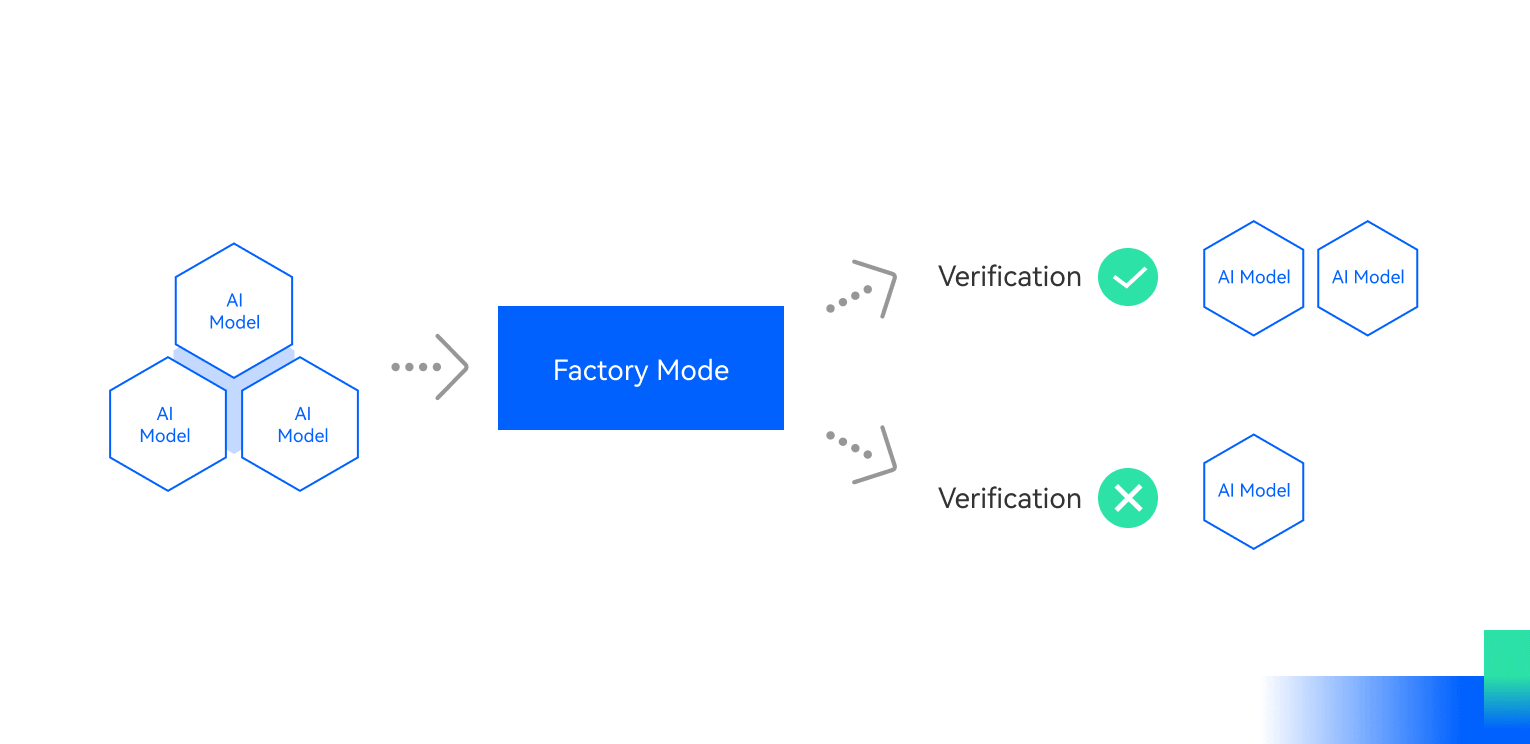

- Verifying the model's performance with real data is an essential step before deployment to ensure production line reliability. The factory mode feature allows batch input of raw images captured by cameras and outputs inference results of production line images to validate the overall algorithm performance.

- Create and manage dedicated datasets for comprehensive validation, with the flexibility to add or remove data based on production line conditions. This ensures the adequacy of validation datasets and reflects the model's performance in real production environments.

- Support viewing inference results from any intermediate algorithm module, enabling efficient and clear data validation, and simplifying the process of identifying problematic models.

- In industrial vision detection scenarios, algorithm solutions often involve multiple models. Traditionally, secondary development requires coding to establish logical relationships between models. AIDI simplifies this by directly exporting Visual Studio projects, eliminating the need to write code or configure dependency libraries. This enables direct use for vision detection algorithm integration tasks, making it accessible for junior engineers, significantly lowering technical barriers, reducing integration time, and improving model development efficiency.

- Provide environmental monitoring tools for real-time monitoring of system environmental status, which helps to promptly identify and resolve problems that may affect the normal operation of programs.