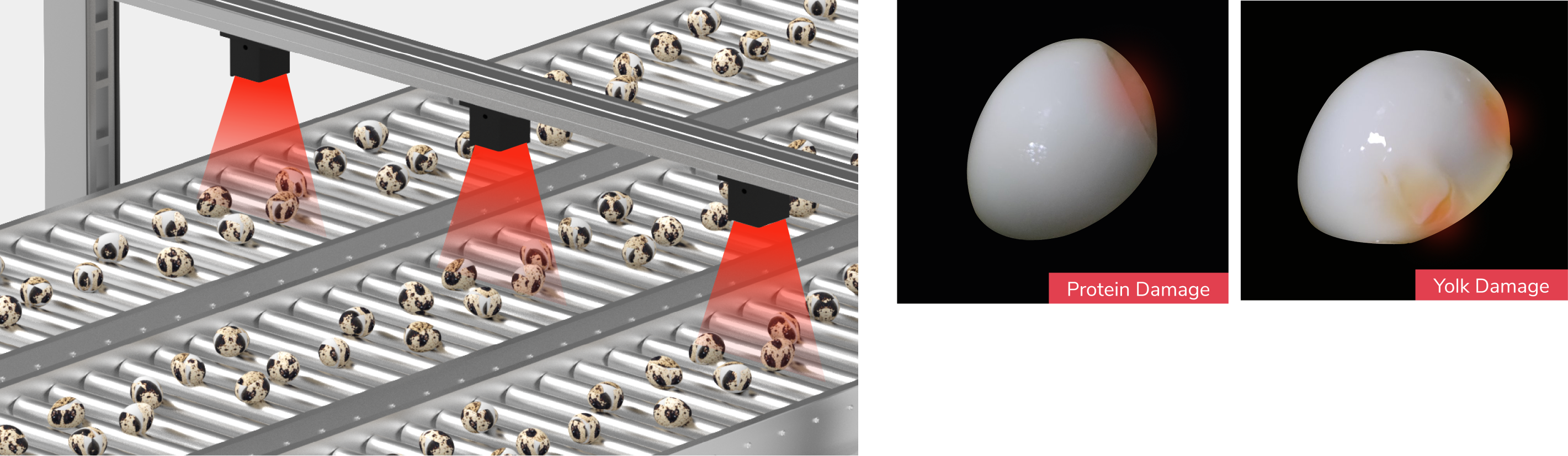

The visual inspection of quail eggs primarily involves detecting defects such as cracks, stains, blood spots, exposed yolk, and shell residue. Currently, this process largely relies on manual visual inspection, which is inefficient and prone to fatigue, resulting in high rates of missed defects and difficulty meeting mass production demands. The core challenges lie in the small size of the eggs, significant color variations, diverse defect patterns, and low contrast, which make traditional machine vision algorithms poorly adaptable and unstable. These methods struggle to efficiently identify subtle and irregular flaws.

As a result, the industry is gradually adopting deep learning-based AI visual inspection solutions to enhance detection accuracy and automation levels.