Quality Control

Leverage AI-powered visual inspection to achieve unprecedented levels of defect detection accuracy across your production line—from micro-components to final packaging—driving down escape rates and safeguarding your brand commitment to excellence.

-

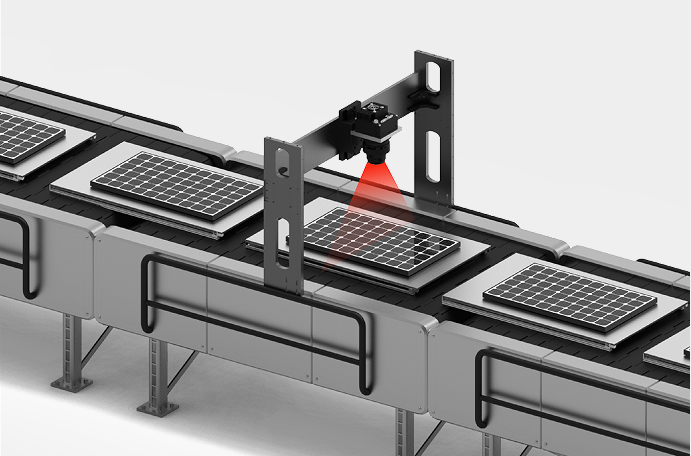

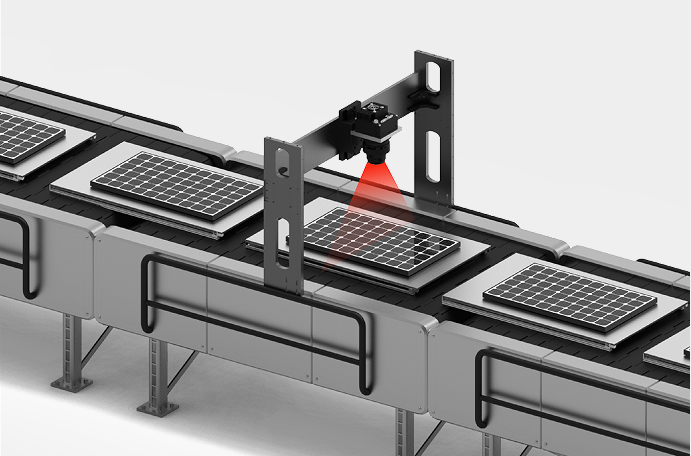

In the process of photovoltaic wafer sorting, traditional algorithms struggle to effectively inspect low-contrast defects, such as contamination, or handle variations in color, resulting in substandard underkill and overkill rates. The customer urgently needs AI algorithms with good inspection resul

In the process of photovoltaic wafer sorting, traditional algorithms struggle to effectively inspect low-contrast defects, such as contamination, or handle variations in color, resulting in substandard underkill and overkill rates. The customer urgently needs AI algorithms with good inspection resul -

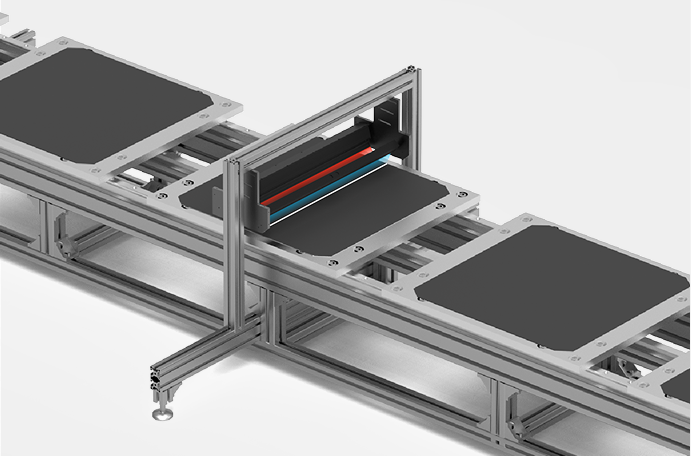

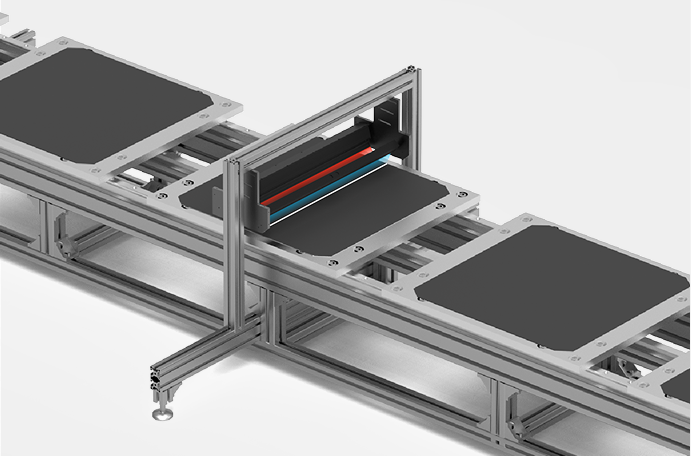

Photovoltaic cells are thin and fragile, making them susceptible to edge chipping and corner breakage during manual handling, which directly impacts product yield. Manual operations also require rotating shifts, resulting in labor-intensive work, high physical strain, and fatigue-induced errors. The

Photovoltaic cells are thin and fragile, making them susceptible to edge chipping and corner breakage during manual handling, which directly impacts product yield. Manual operations also require rotating shifts, resulting in labor-intensive work, high physical strain, and fatigue-induced errors. The -

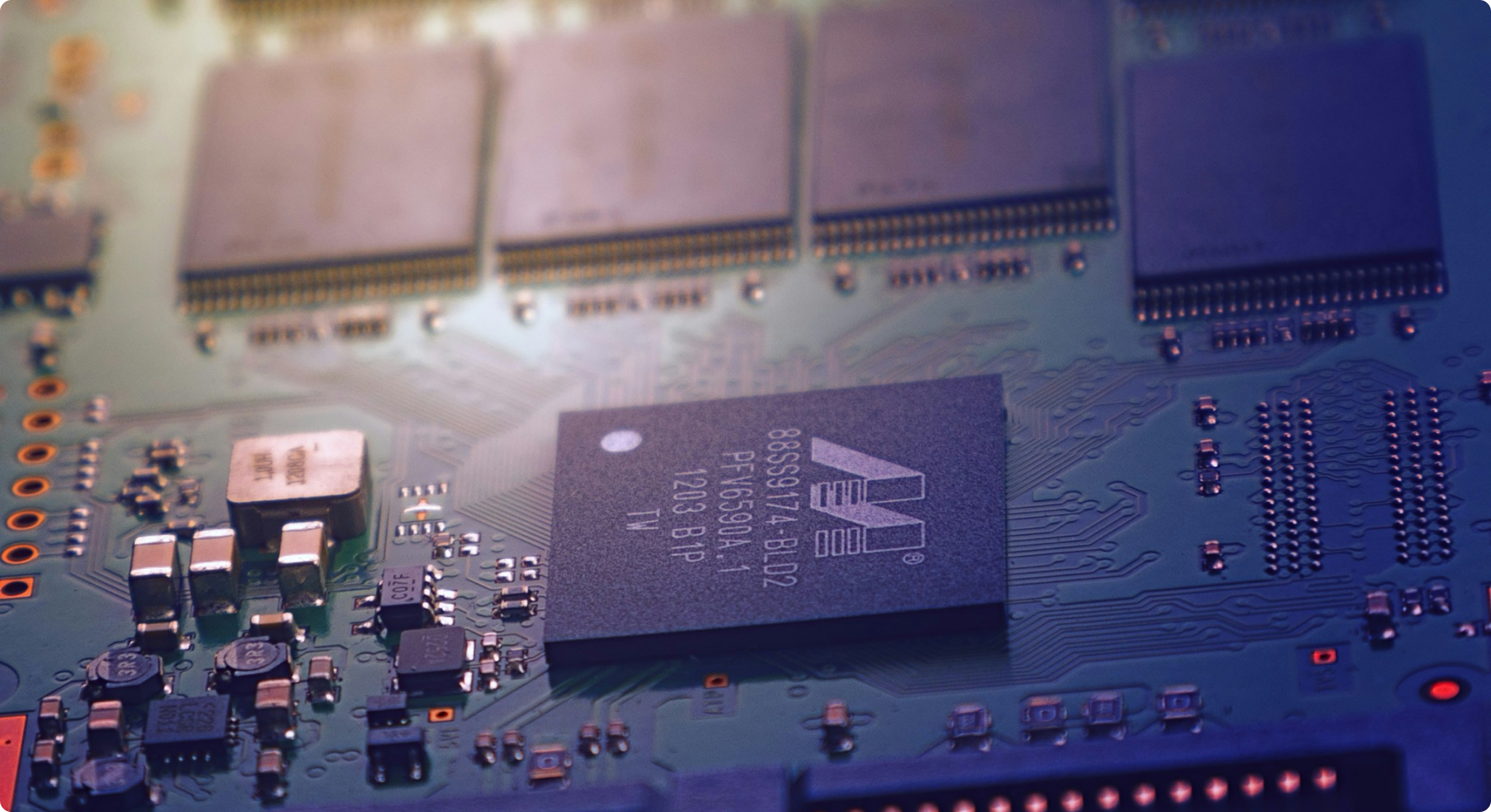

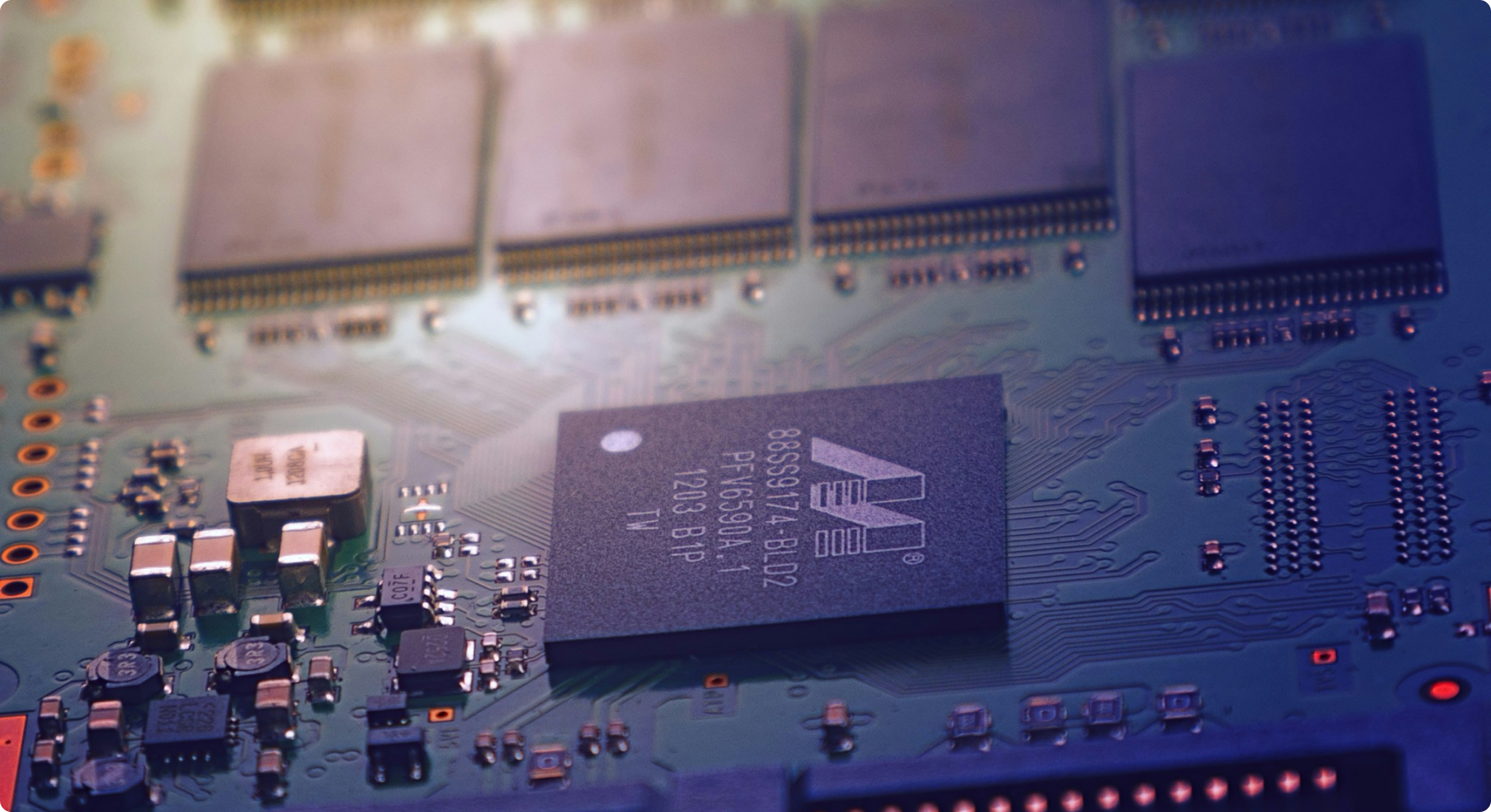

Chip Wire Bond inspection is a crucial detection process in the semiconductor packaging stage, focusing on the connection quality of bonded wires. By examining the connection status of bonding wires such as gold wires and copper wires, it ensures the stable transmission of internal circuit signals o

Chip Wire Bond inspection is a crucial detection process in the semiconductor packaging stage, focusing on the connection quality of bonded wires. By examining the connection status of bonding wires such as gold wires and copper wires, it ensures the stable transmission of internal circuit signals o -

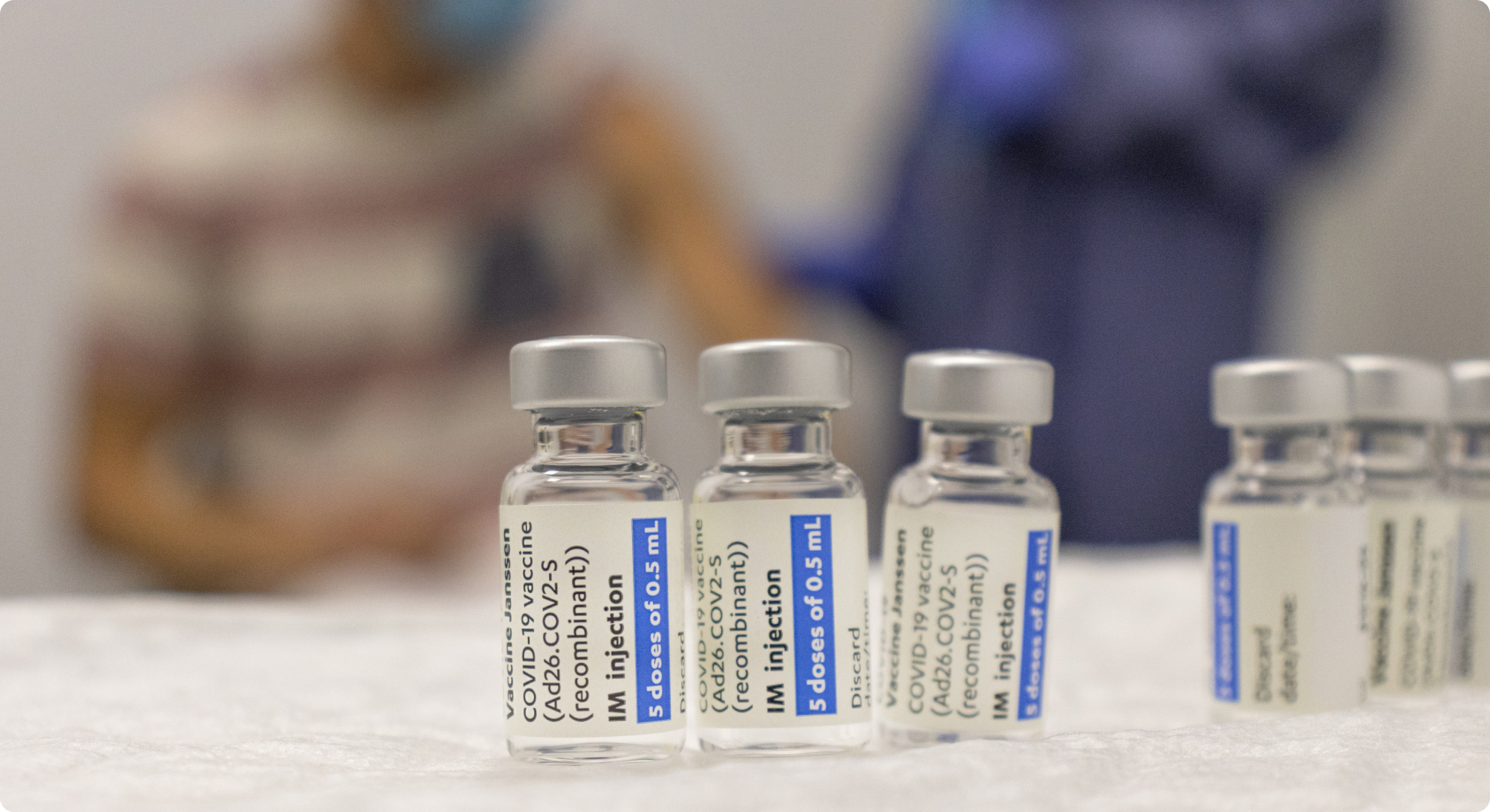

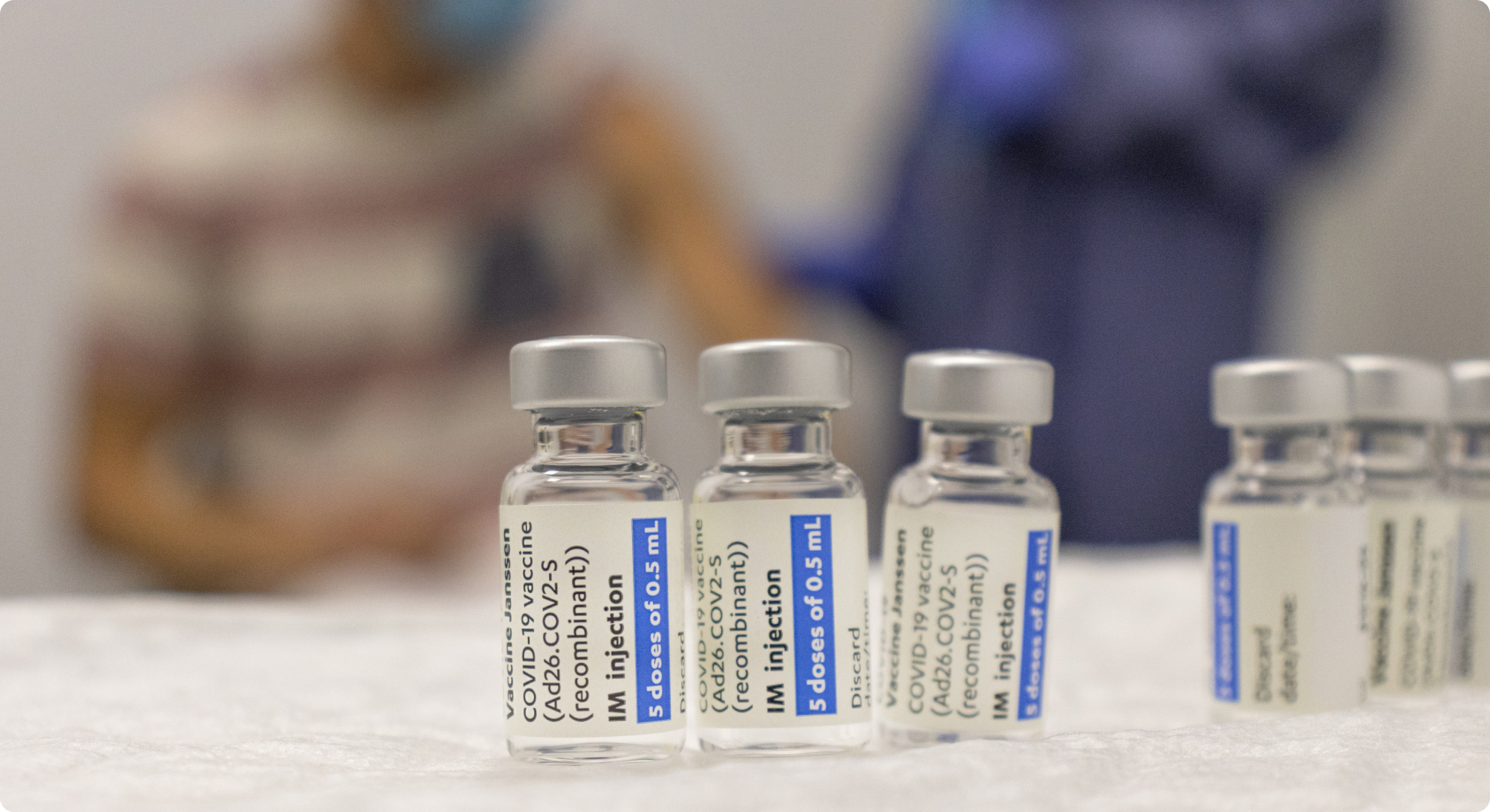

Medicine bottles are core containers for pharmaceutical packaging, mostly made of plastic (such as PP, PE) or glass. They typically include structures like the bottle body, bottle mouth threads, and bottle cap, and must meet pharmaceutical standards for sealing and contamination prevention.The inspe

Medicine bottles are core containers for pharmaceutical packaging, mostly made of plastic (such as PP, PE) or glass. They typically include structures like the bottle body, bottle mouth threads, and bottle cap, and must meet pharmaceutical standards for sealing and contamination prevention.The inspe -

Medicine bottles are core containers for pharmaceutical packaging, mostly made of plastic (such as PP, PE) or glass. They typically include structures like the bottle body, bottle mouth threads, and bottle cap, and must meet pharmaceutical standards for sealing and contamination prevention.The inspe

Medicine bottles are core containers for pharmaceutical packaging, mostly made of plastic (such as PP, PE) or glass. They typically include structures like the bottle body, bottle mouth threads, and bottle cap, and must meet pharmaceutical standards for sealing and contamination prevention.The inspe -

Currently, the appearance inspection of instant noodle cakes is crucial in high-speed automated production lines, yet it faces numerous challenges. Production lines operate at extremely high speeds, requiring the detection of defects as small as 0.5mm, such as oil residue, dark spots, and burnt resi

Currently, the appearance inspection of instant noodle cakes is crucial in high-speed automated production lines, yet it faces numerous challenges. Production lines operate at extremely high speeds, requiring the detection of defects as small as 0.5mm, such as oil residue, dark spots, and burnt resi