Electric Vehicle Battery

In 2024, the global capacity of installed power batteries reached 895 GWh, a year-on-year increase of 27.2%. Currently, prismatic, pouch, and cylindrical batteries coexist and the industry is advancing toward green, low-carbon, and high-quality development. In the future, power battery production will focus more on the application of intelligent, automated, and flexible technologies, striving for excellence in quality control at every production stage from individual cells to battery packs. Defect inspection, as a core part of quality control, is an indispensable component.

Aqrose AI Solution Overview

Aqrose Technology's AI visual inspection solution for power batteries covers the entire process from "electrode manufacturing → cell manufacturing → module/Pack assembly" and is compatible with multi-form batteries. Leveraging AI visual technology, it effectively addresses quality control challenges such as large production volumes, numerous process control points, and complex defect types.

Full-process Inspection of EV Batteries

Electrode Manufacturing Process Stage

Cell Manufacturing Process Stage

Module/Pack Manufacturing Process Stage

Success Cases

-

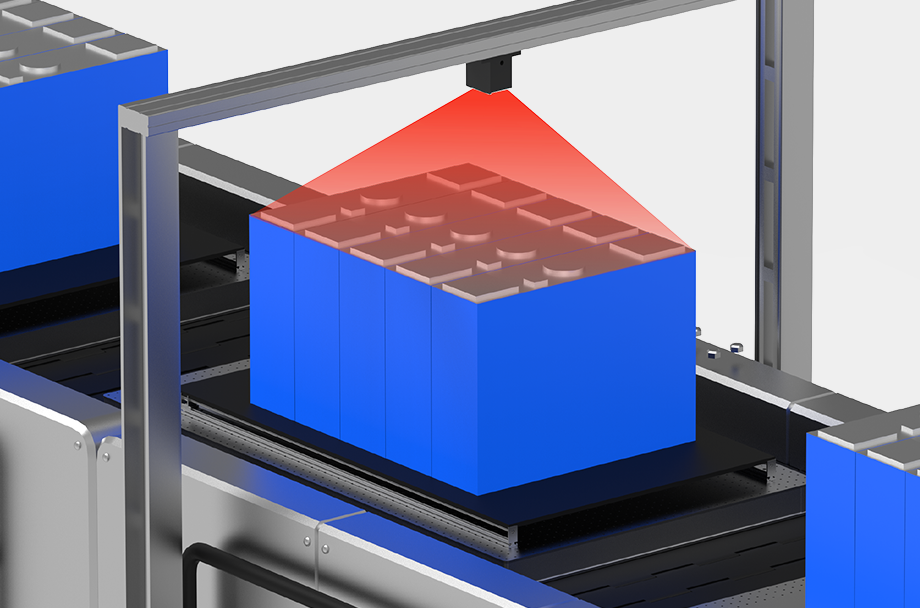

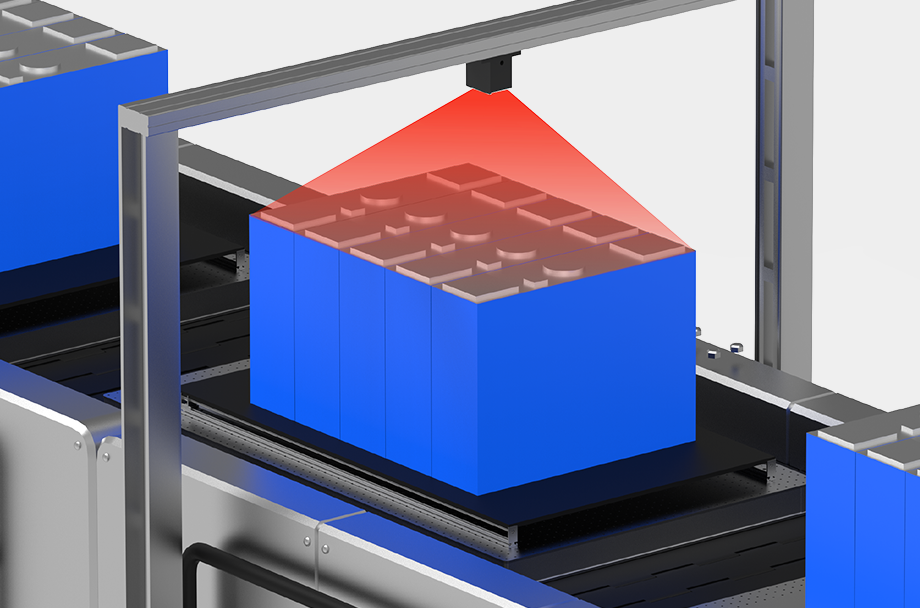

The welding quality of battery sealing nails critically impacts battery performance. Defects such as pinholes, cracks, burst points, pits, lifted nails, steps, discoloration, weld ash, incomplete welds, and slag may occur after welding, potentially causing loose casings, air leaks, or electrolyte le

The welding quality of battery sealing nails critically impacts battery performance. Defects such as pinholes, cracks, burst points, pits, lifted nails, steps, discoloration, weld ash, incomplete welds, and slag may occur after welding, potentially causing loose casings, air leaks, or electrolyte le -

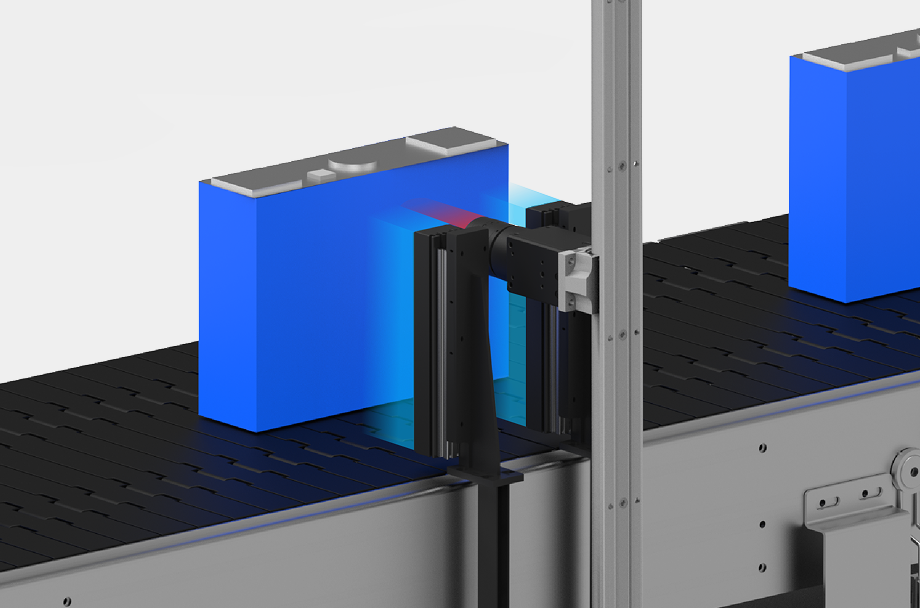

Cylindrical lithium-ion batteries offer market advantages due to mature technology and high standardization. However, to maintain competitiveness, manufacturers must improve production quality and adopt smart manufacturing strategies. Defects such as scratches, black spots, contamination, ring marks

Cylindrical lithium-ion batteries offer market advantages due to mature technology and high standardization. However, to maintain competitiveness, manufacturers must improve production quality and adopt smart manufacturing strategies. Defects such as scratches, black spots, contamination, ring marks -

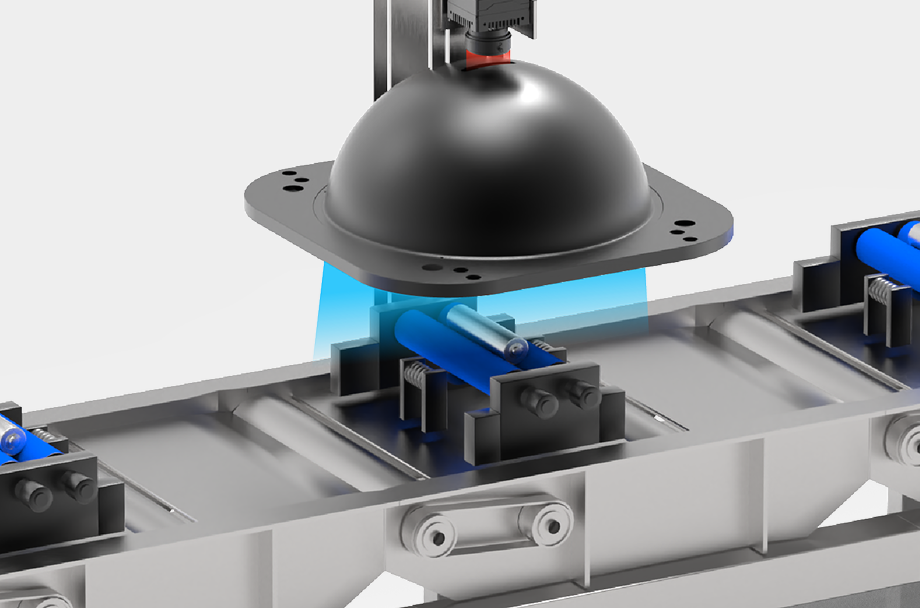

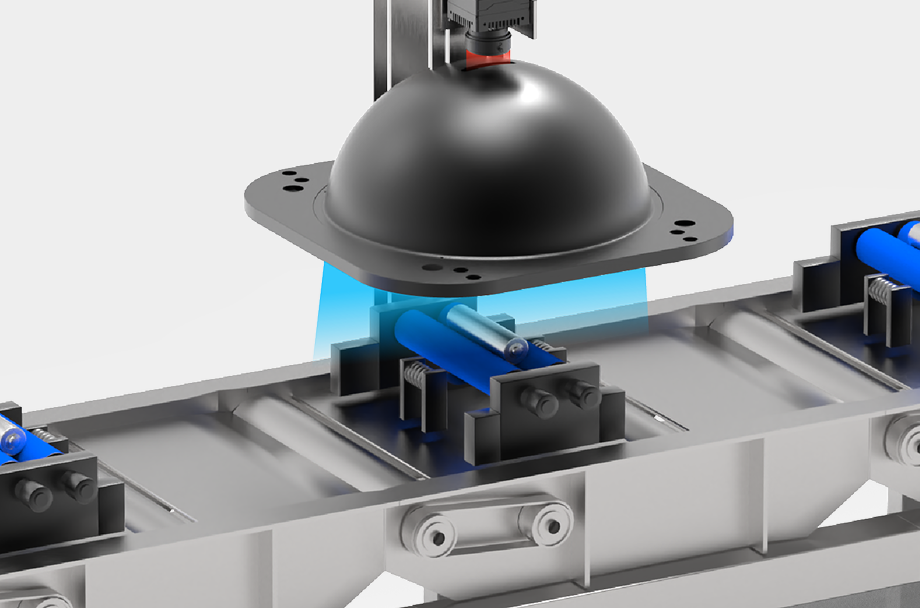

Structural adhesive layers in lithium battery modules secure and protect internal components. Defects like bubbles or cracks can reduce performance or cause safety risks. Current quality inspection requires destructive dismantling after adhesive curing, resulting in waste. Due to the adhesive’s high

Structural adhesive layers in lithium battery modules secure and protect internal components. Defects like bubbles or cracks can reduce performance or cause safety risks. Current quality inspection requires destructive dismantling after adhesive curing, resulting in waste. Due to the adhesive’s high -

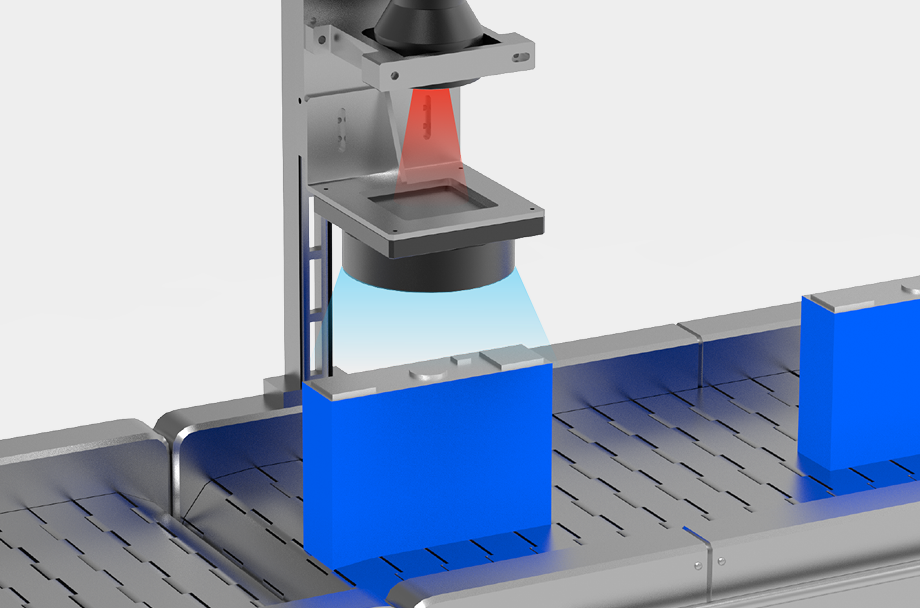

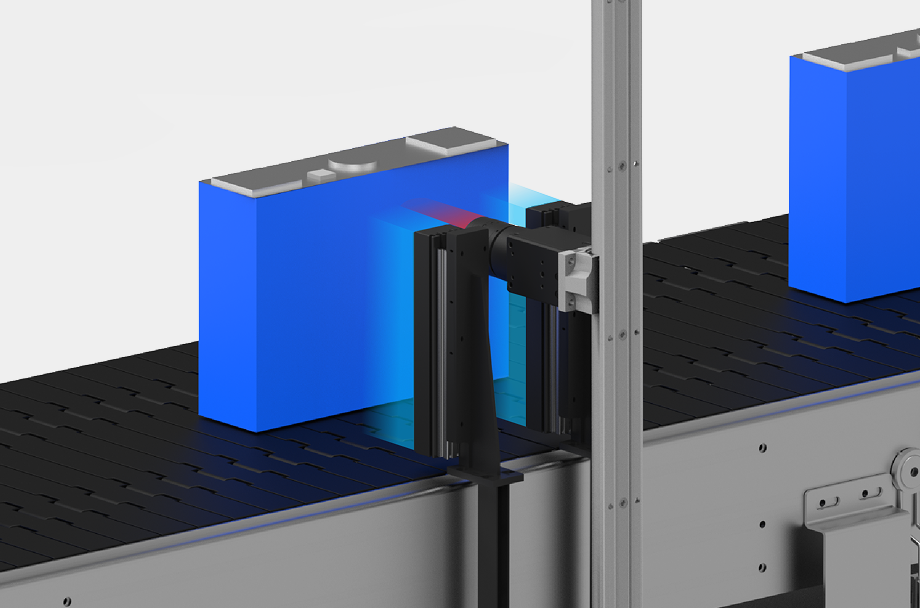

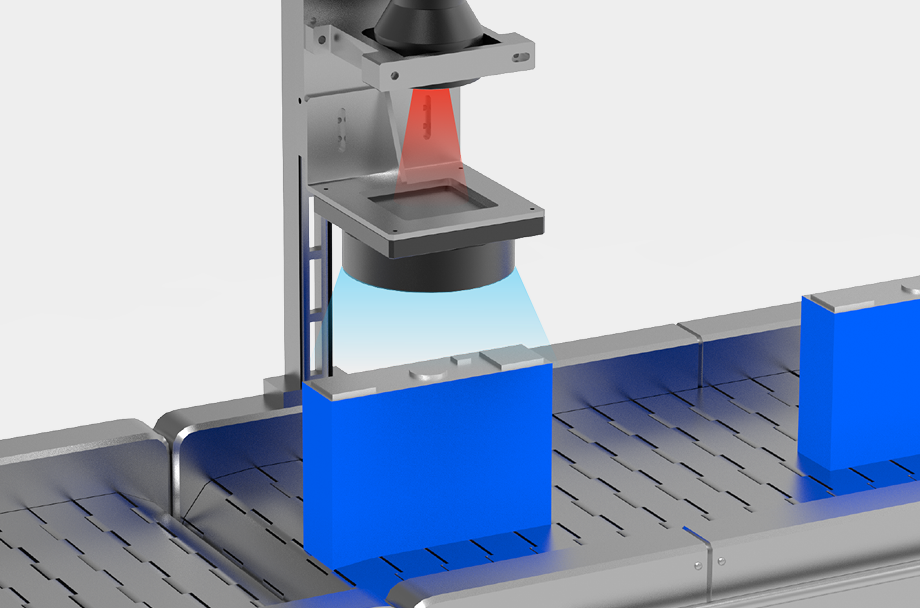

In power batteries, the blue protective film (industry-called "blue film") is a core outer layer material, ensuring fixation, insulation, dustproofing, and waterproofing as a key barrier between cells and the environment. Yet scratches, damage, contamination, wrinkles, or depressions often occur, ha

In power batteries, the blue protective film (industry-called "blue film") is a core outer layer material, ensuring fixation, insulation, dustproofing, and waterproofing as a key barrier between cells and the environment. Yet scratches, damage, contamination, wrinkles, or depressions often occur, ha