Automotive

AI visual inspection is widely used in automotive for defect inspection, assembly verification, and precision measurement. It tackles diverse components, complex defects, and fast product changes. With strong feature learning and adaptability, AI can overcome traditional algorithms' limitations and drives higher automation, intelligence, and reliability in manufacturing.

Aqrose AI Solution Overview

Aqrose Technology delivers AI vision solutions for the automotive industry, enabling high-precision inspection of components, assembly verification, and defect inspection. Applying deep learning to critical scenarios like engine blocks and motor stators, it enhances quality control and drives intelligent, automated manufacturing.

Full-process Inspection of Automotive Industry

Stamping Process

Welding Process

Painting Process

General Assembly Process

Success Cases

-

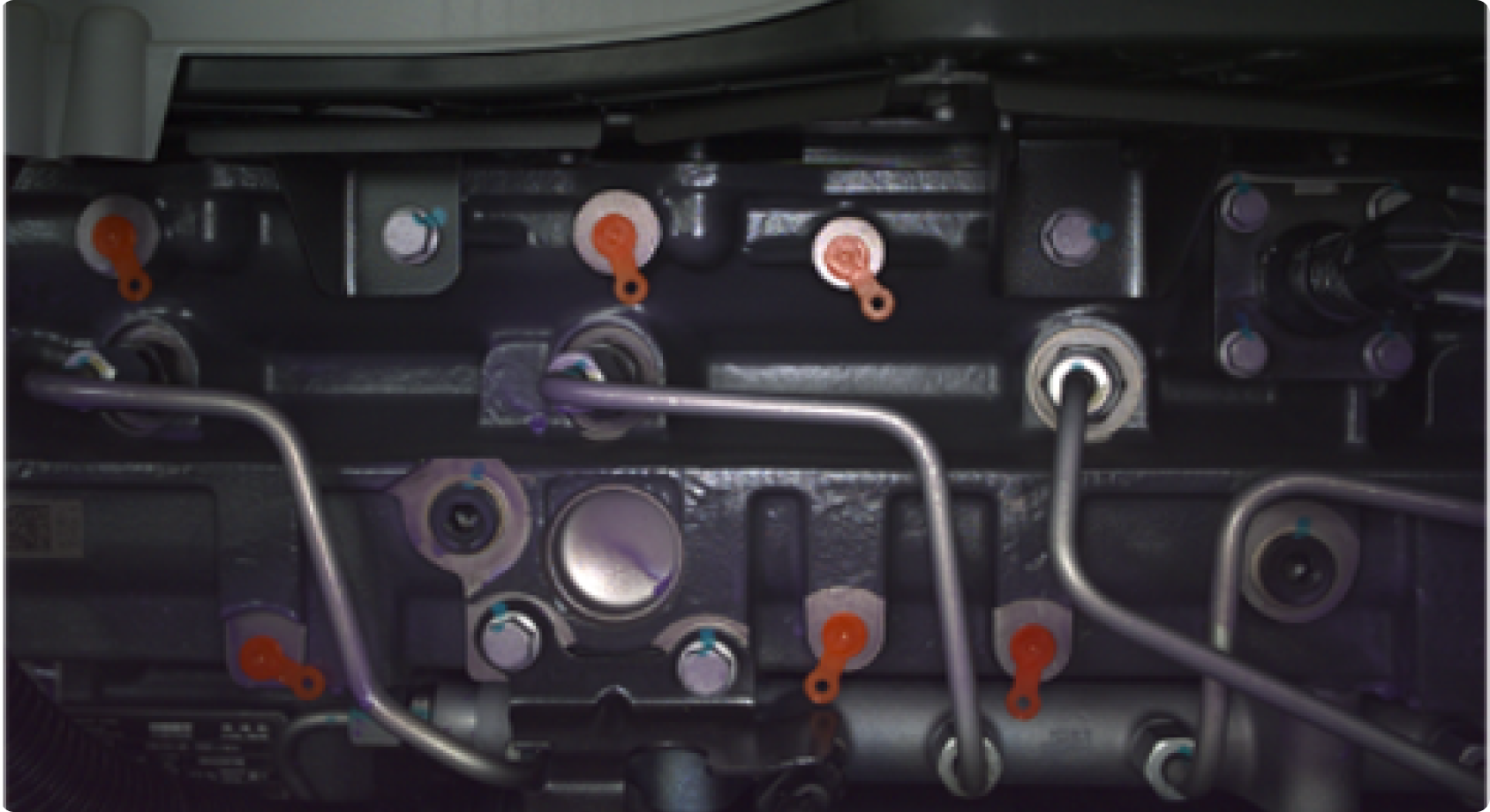

In the transmission differential bolt adhesive application process, defects such as missing adhesive or adhesive discontinuities may occur. Traditional threshold-based vision sensors have limited detection capabilities, particularly exhibiting high missed detection rates for adhesive discontinuities

In the transmission differential bolt adhesive application process, defects such as missing adhesive or adhesive discontinuities may occur. Traditional threshold-based vision sensors have limited detection capabilities, particularly exhibiting high missed detection rates for adhesive discontinuities -

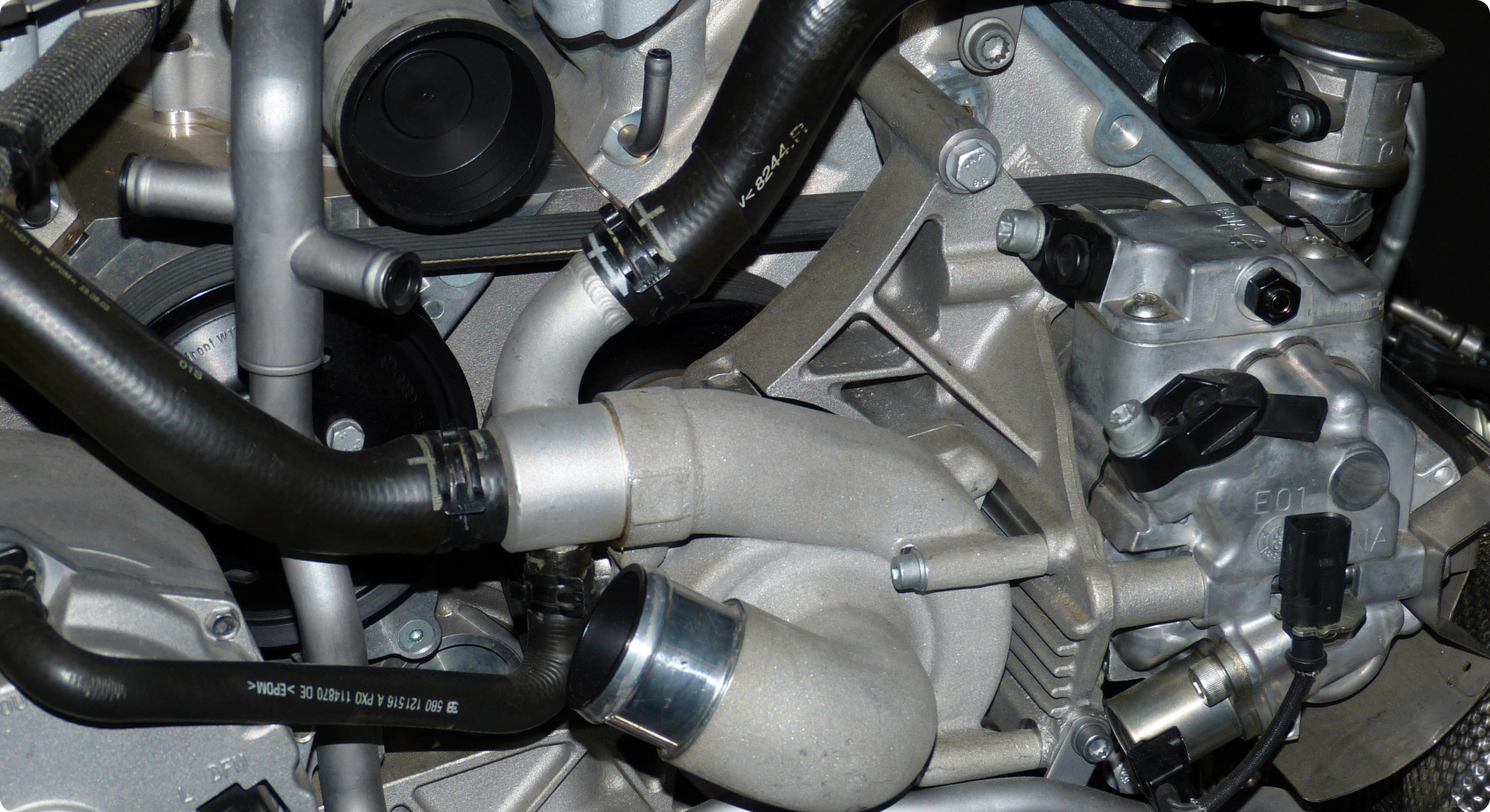

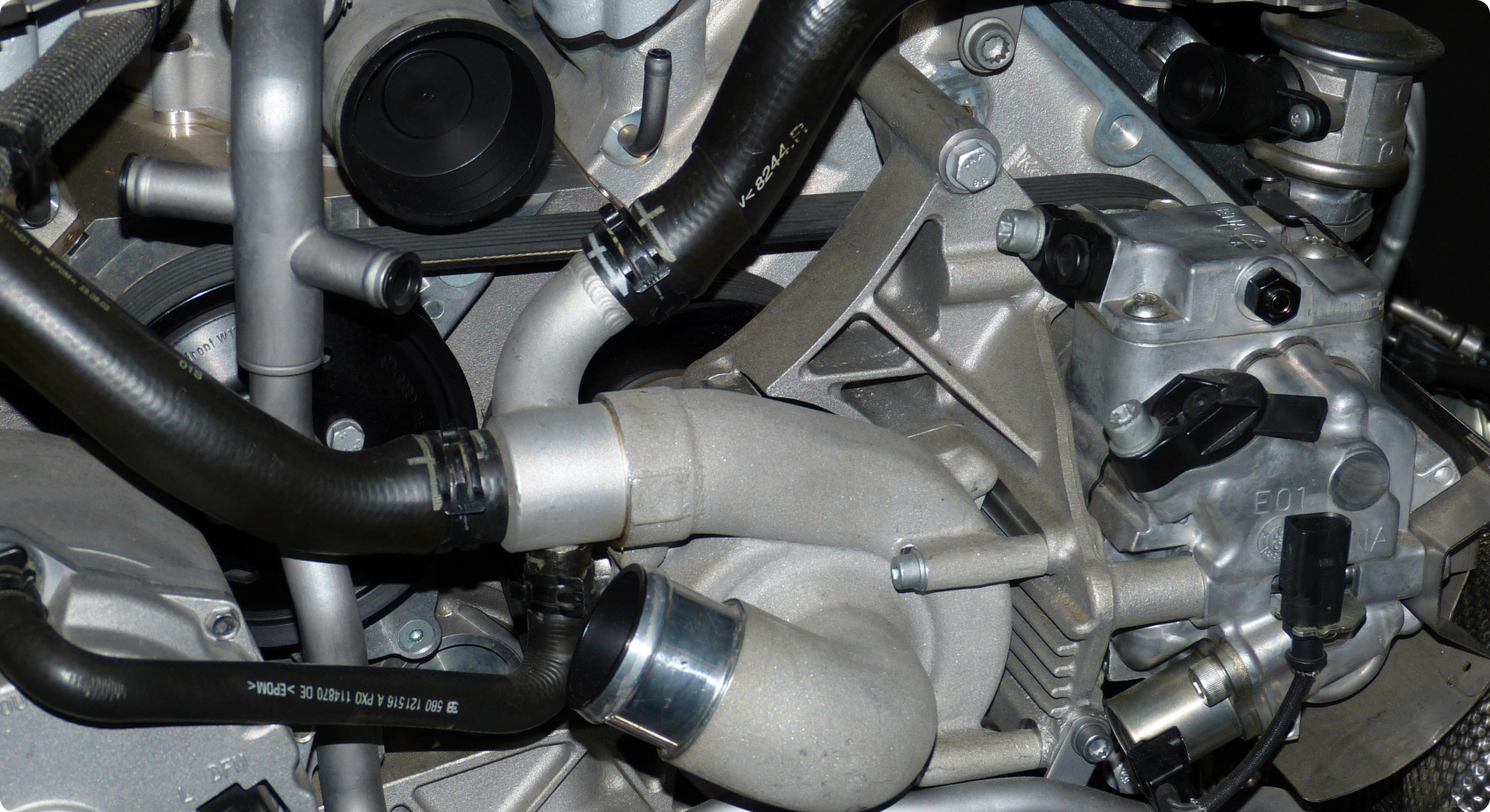

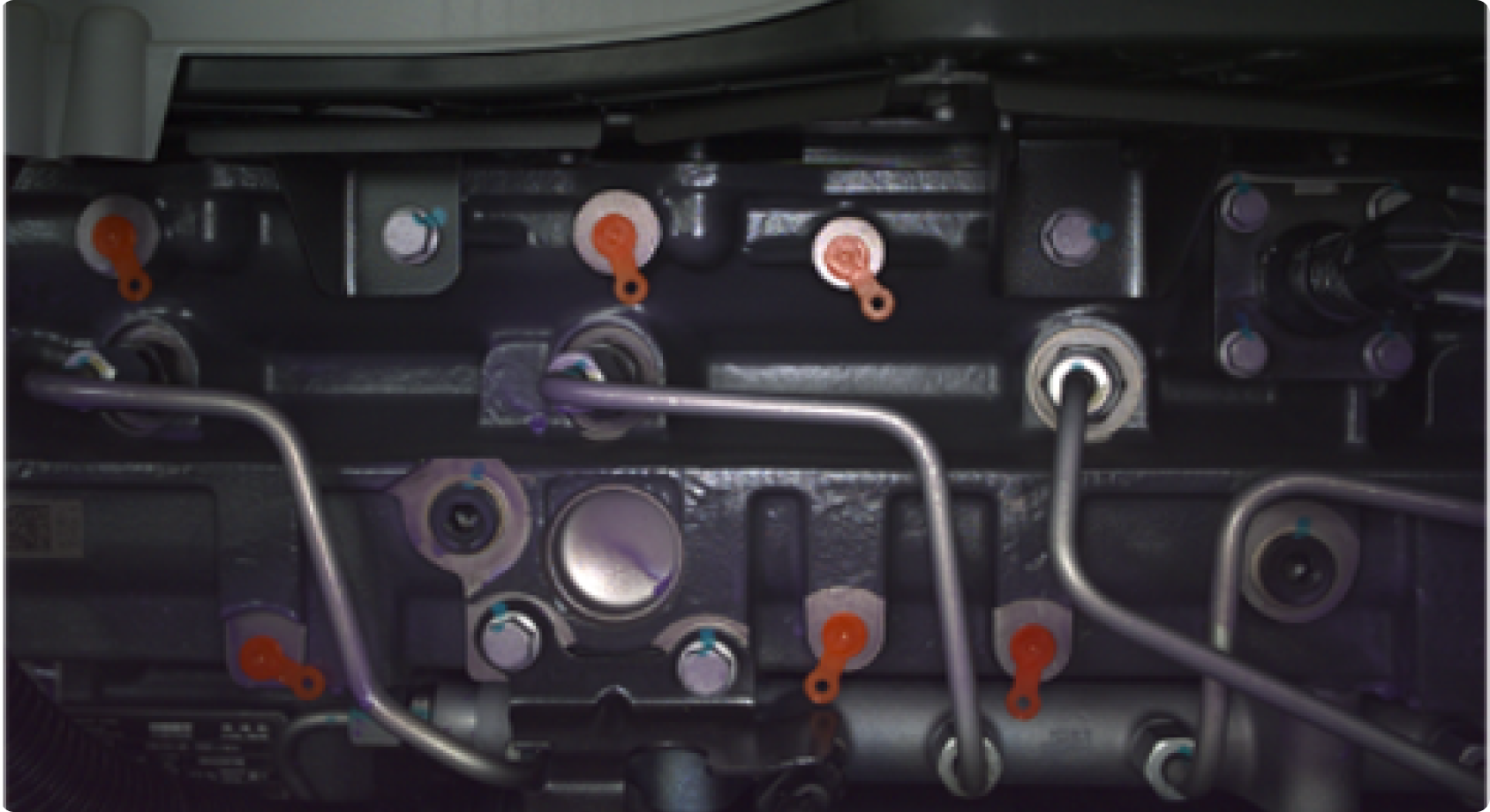

Engine assembly inspection requires ensuring that the dimensions, shapes, and positions of all components meet design specifications. However, current vision inspection solutions relying on traditional algorithms struggle to address challenges such as multiple engine models, numerous inspection item

Engine assembly inspection requires ensuring that the dimensions, shapes, and positions of all components meet design specifications. However, current vision inspection solutions relying on traditional algorithms struggle to address challenges such as multiple engine models, numerous inspection item -

Engine cylinder blocks are prone to low-contrast micro-defects such as sand holes and cracks during the casting process. Traditional inspection methods, including visual inspection, touch testing, and ultrasonic detection, struggle to achieve comprehensive and accurate surface defect detection, lead

Engine cylinder blocks are prone to low-contrast micro-defects such as sand holes and cracks during the casting process. Traditional inspection methods, including visual inspection, touch testing, and ultrasonic detection, struggle to achieve comprehensive and accurate surface defect detection, lead -

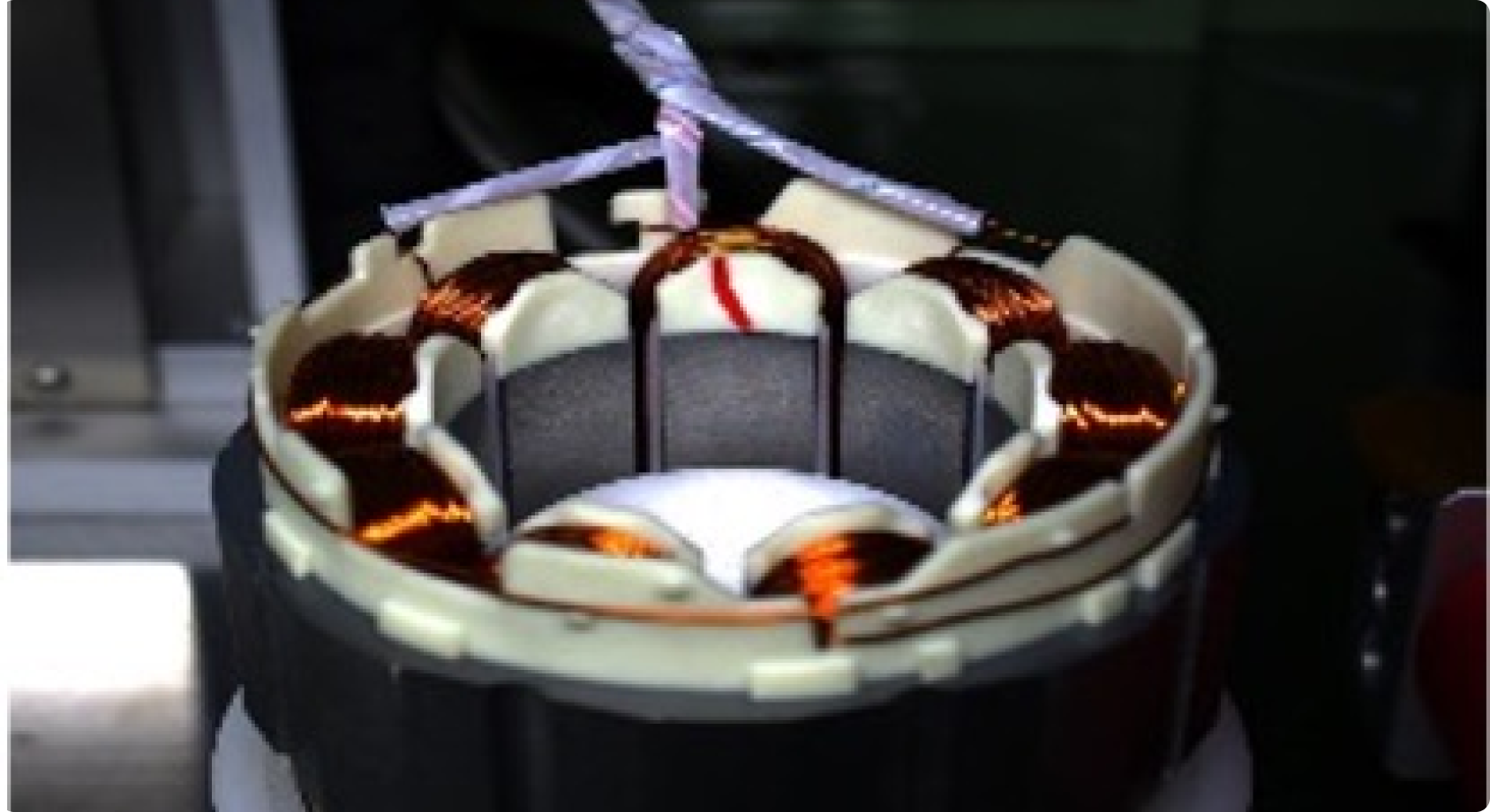

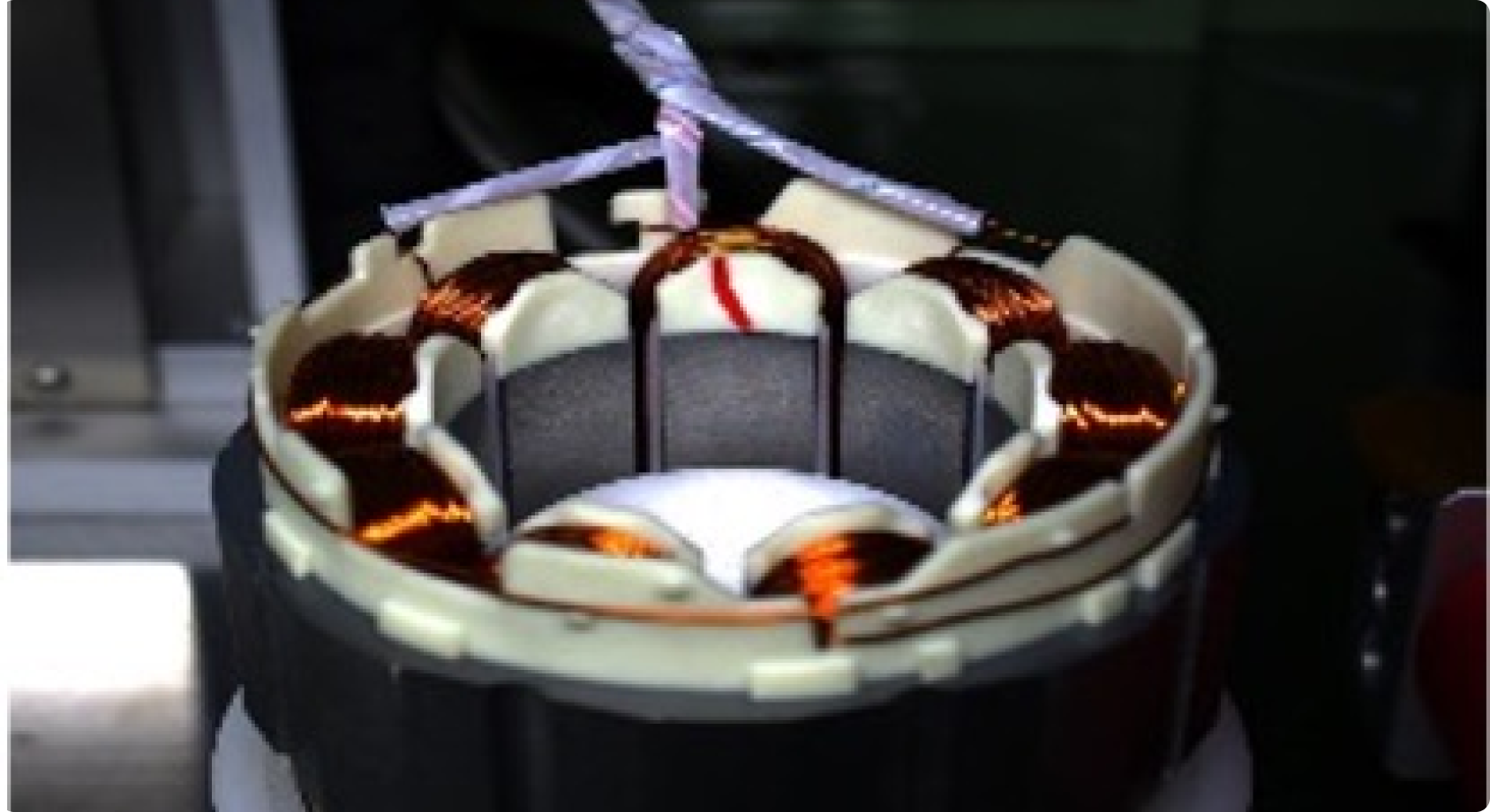

Motor stator structural components involve over 20 models with significant dimensional variations and diverse defect types (e.g., insulation paper damage, copper wire misalignment). Traditional vision inspection solutions struggle to adapt to rapid model changes and lack the capability to reliably d

Motor stator structural components involve over 20 models with significant dimensional variations and diverse defect types (e.g., insulation paper damage, copper wire misalignment). Traditional vision inspection solutions struggle to adapt to rapid model changes and lack the capability to reliably d -

In automotive manufacturing, engine assembly is a complex process guided by clear, systematic standard operating procedures (SOPs). However, due to the intricate nature of these procedures, assembly line workers often make mistakes such as incorrect installation, missing components, or reversing ass

In automotive manufacturing, engine assembly is a complex process guided by clear, systematic standard operating procedures (SOPs). However, due to the intricate nature of these procedures, assembly line workers often make mistakes such as incorrect installation, missing components, or reversing ass