Electronic Components

Electronic components—from passive to active types—are evolving toward higher performance, smaller size, and greater reliability. Advances in microfabrication, packaging, and SMT have raised performance benchmarks but also introduced complex quality risks, including sub-millimeter defects, contamination, solder issues, and hidden flaws, which can trigger costly failures.

Aqrose AI Solution Overview

Aqrose Technology’s AI visual inspection solution monitors the full component manufacturing process—including material preparation, functional structure formation, conductive interconnection, and encapsulation. Leveraging deep learning, it detects sub-millimeter defects, surface contamination, and packaging anomalies with high speed and precision, ensuring consistent quality, higher yield, and robust defect detection.

Full-process Inspection of Electronic components

Material Preparation

Functional Structure Formation

Conductive Interconnection

Encapsulation

Success Cases

-

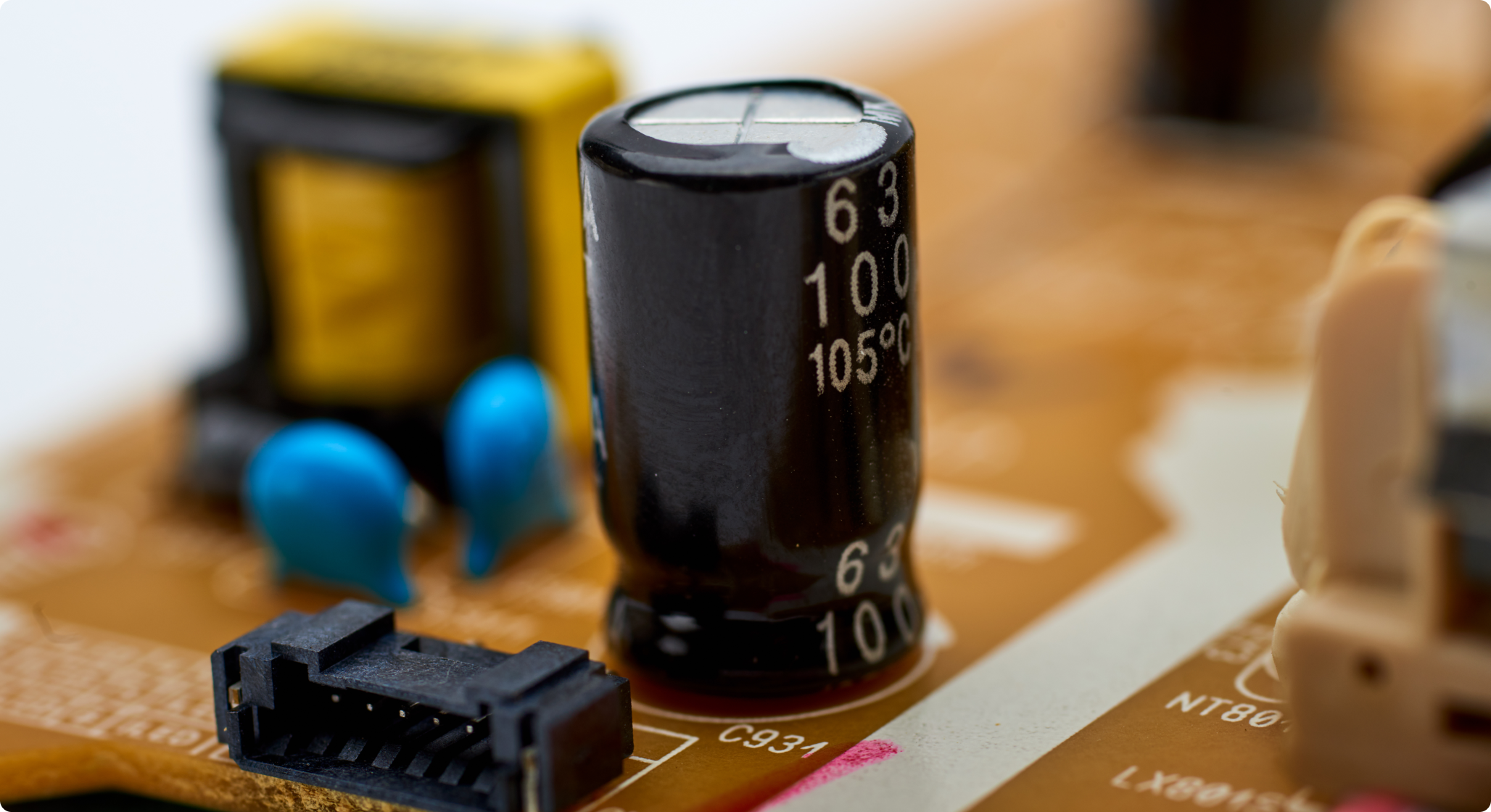

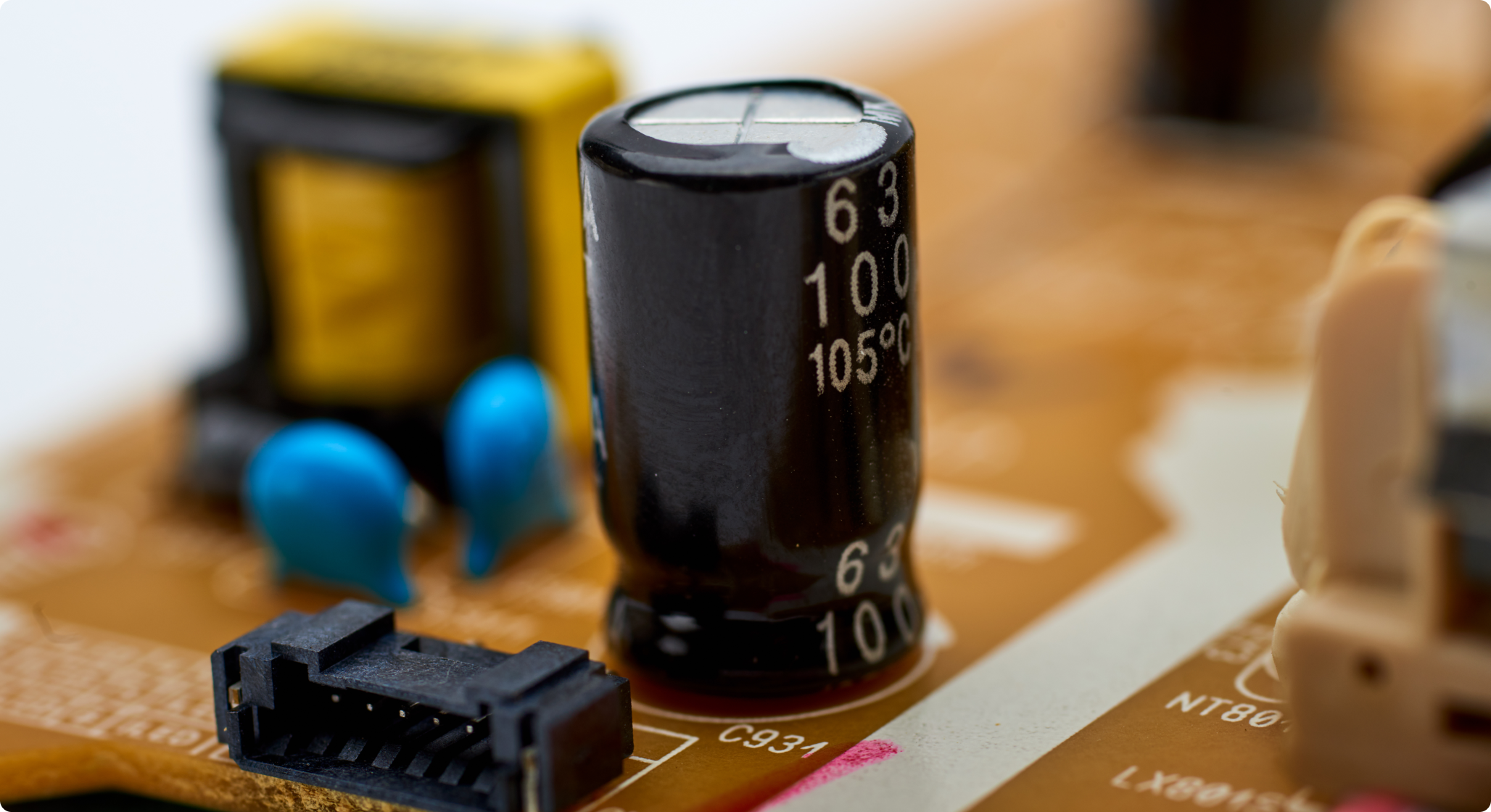

As capacitor quality demands rise, diverse models and subtle defects challenge manual and traditional algorithm-based inspection. Low efficiency and missed low-contrast flaws drive manufacturers to adopt AI-based inspection, ensuring higher accuracy, speed, and adaptability to meet modern electronic

As capacitor quality demands rise, diverse models and subtle defects challenge manual and traditional algorithm-based inspection. Low efficiency and missed low-contrast flaws drive manufacturers to adopt AI-based inspection, ensuring higher accuracy, speed, and adaptability to meet modern electronic -

In an electronic component plant, defect checks rely on microscopes and manual judgment, spotting issues like contamination, cracks, or wire breaks. This process is slow and subjective, prompting the client to seek AI-based intelligent inspection to boost accuracy, efficiency, and automated defect a

In an electronic component plant, defect checks rely on microscopes and manual judgment, spotting issues like contamination, cracks, or wire breaks. This process is slow and subjective, prompting the client to seek AI-based intelligent inspection to boost accuracy, efficiency, and automated defect a -

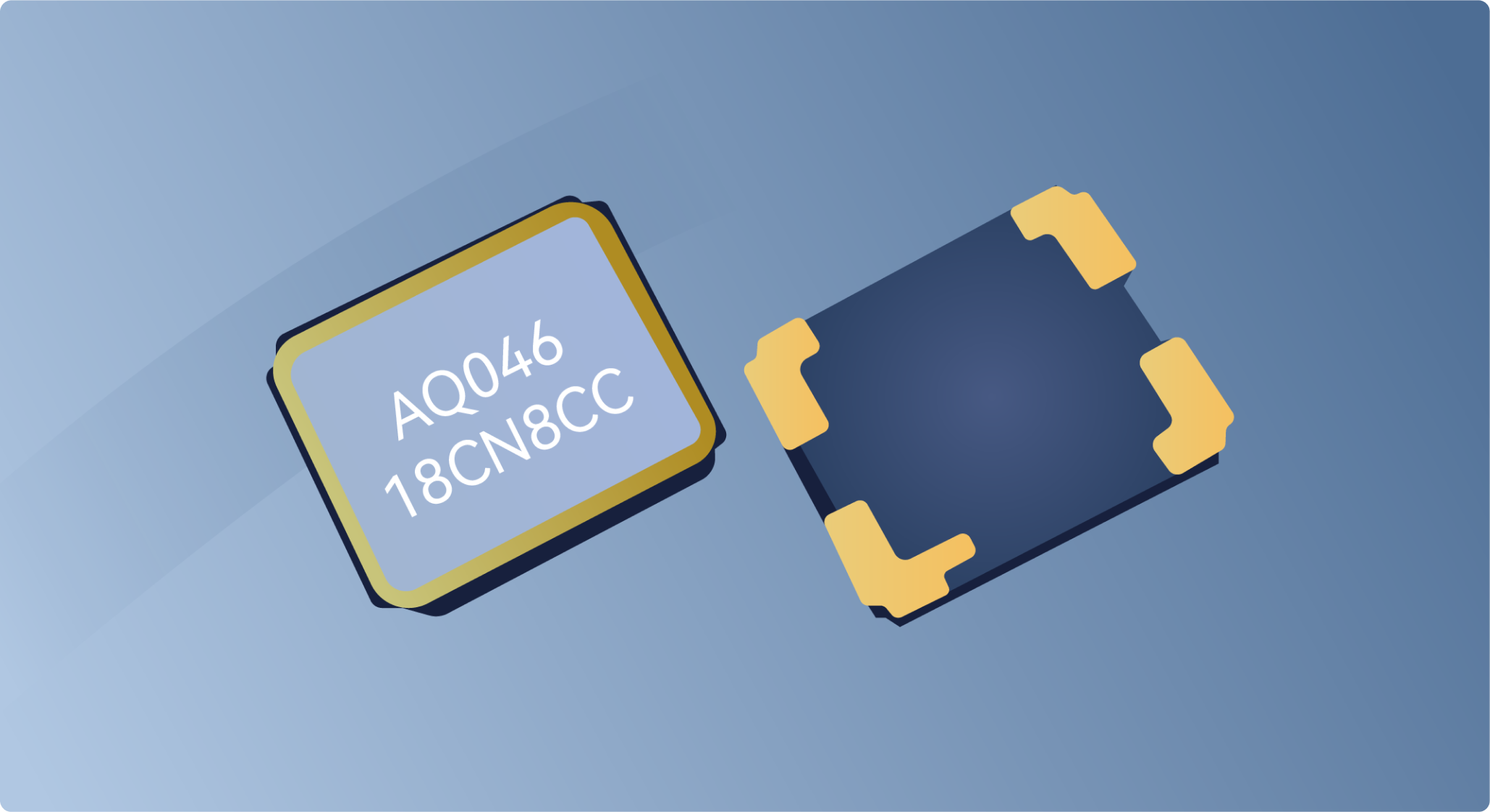

Quartz crystal oscillators are passive components that deliver highly stable, precise frequencies for communications, aerospace, automotive, and other fields. As inspection standards rise, traditional systems fail to detect appearance defects like contamination or scratches. Manufacturers face bottl

Quartz crystal oscillators are passive components that deliver highly stable, precise frequencies for communications, aerospace, automotive, and other fields. As inspection standards rise, traditional systems fail to detect appearance defects like contamination or scratches. Manufacturers face bottl