Pharmaceutical

In the pharmaceutical industry, industrial AI visual inspection covers packaging label checks, bottle/blister cosmetic inspection, and production quality control. Its automation and high precision boosts efficiency and reduces manual workload. Yet pain points remain: complex environments hurt data quality; diverse specs hinder universal algorithms; tiny defects are hard to capture stably; annotation is costly.

Aqrose AI Solution Overview

Aqrose provides AIDI-based visual inspection solutions for typical applications in the pharmaceutical industry. For Blister Packaging Inspection, its segmentation algorithm addresses low-contrast and small-area defect issues, with a speed of 400pcs/min. For Three-Phase Code Inspection, positioning and recognition algorithms accurately locate printing positions, featuring strong anti-interference and over 99% accuracy. For Cosmetic Inspection of Medical Bottles, the "fast detection + segmentation" algorithm achieves a 90% first-pass rate, with a universal model adapting to product changes.

Full-process Inspection of Pharmaceutical Industry

Packaging Inspection

Critical Information Recognition

Container & Product Appearance

Success Cases

-

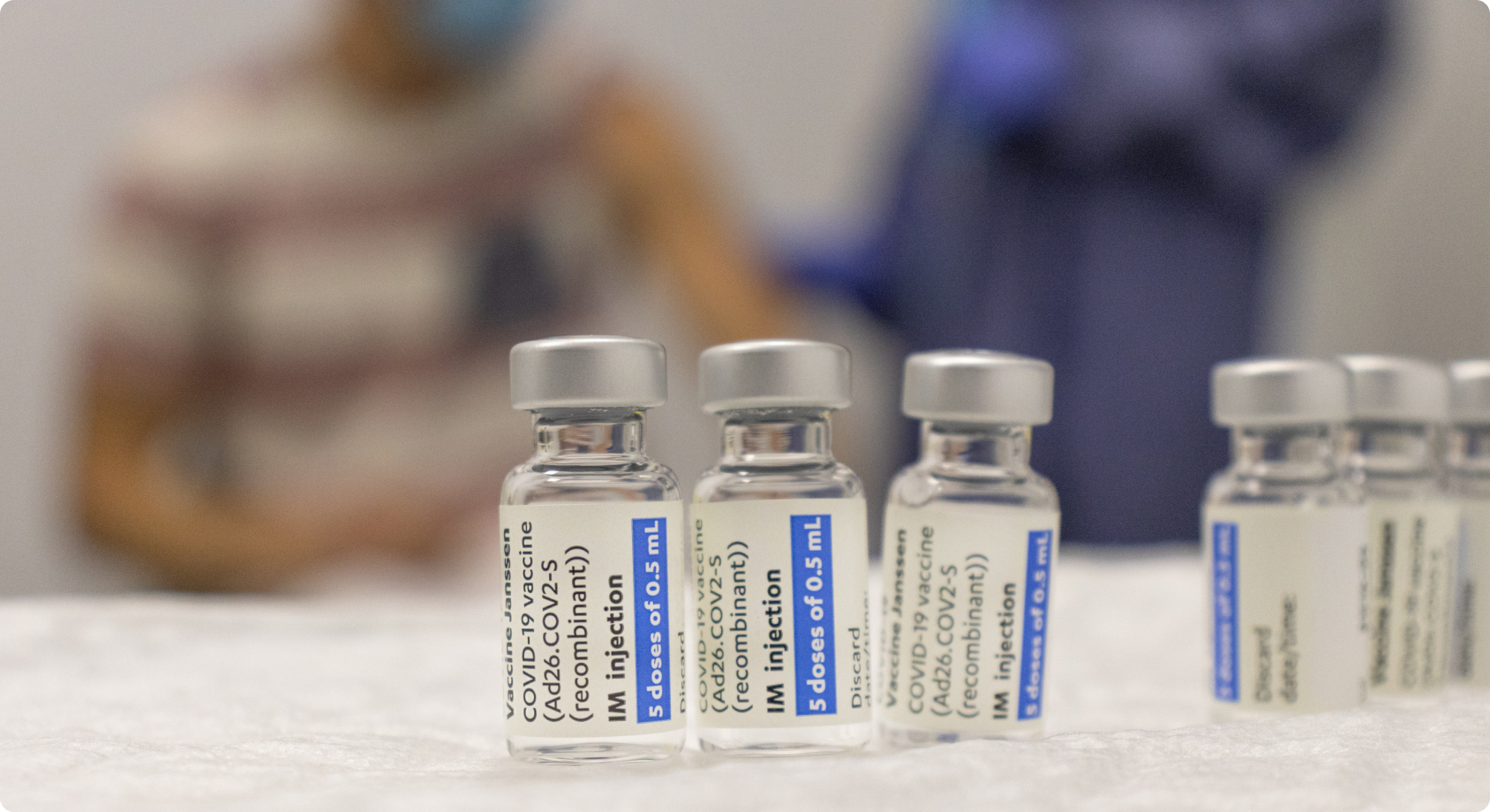

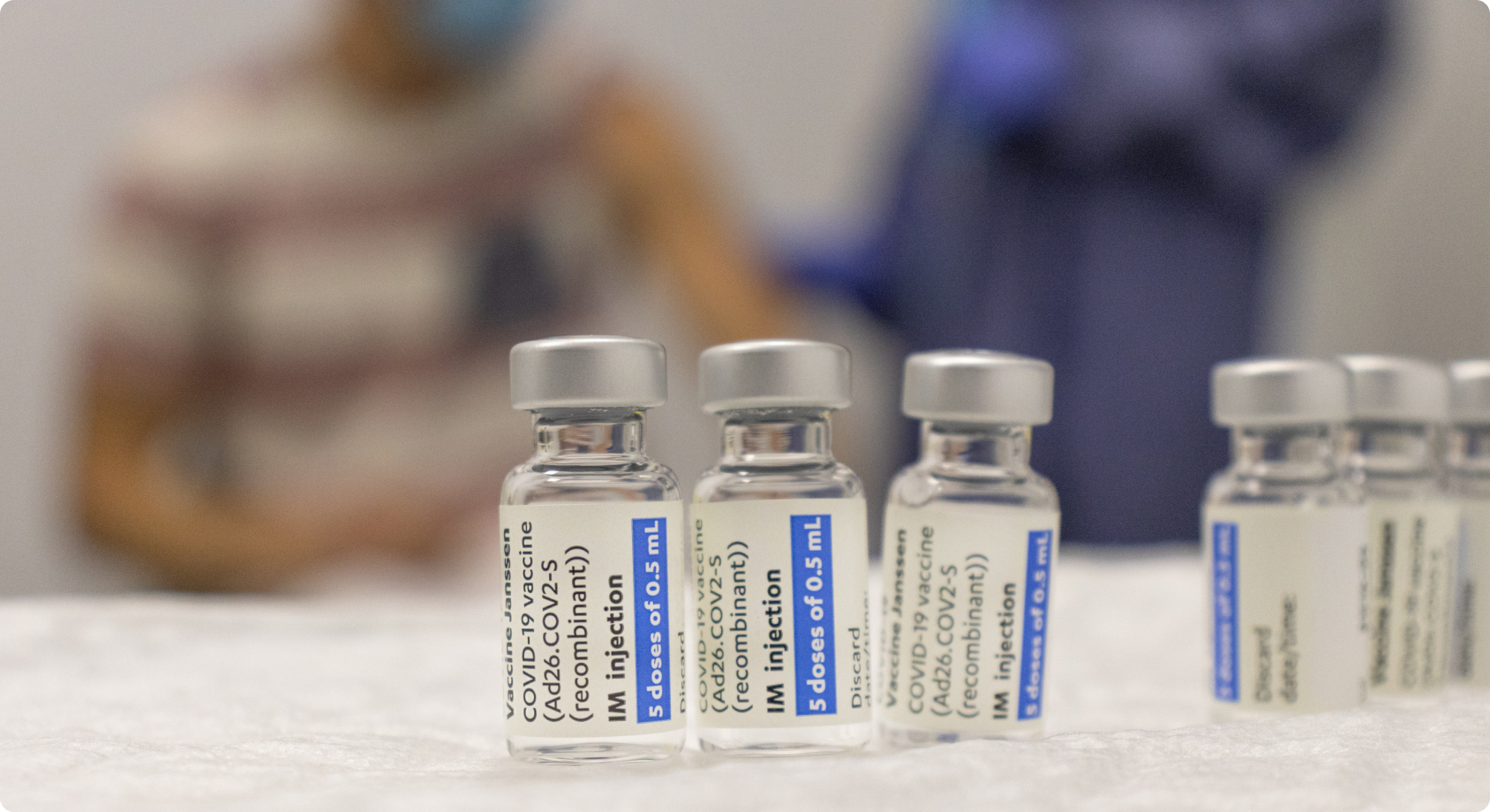

Medicine bottles are core containers for pharmaceutical packaging, mostly made of plastic (such as PP, PE) or glass. They typically include structures like the bottle body, bottle mouth threads, and bottle cap, and must meet pharmaceutical standards for sealing and contamination prevention.The inspe

Medicine bottles are core containers for pharmaceutical packaging, mostly made of plastic (such as PP, PE) or glass. They typically include structures like the bottle body, bottle mouth threads, and bottle cap, and must meet pharmaceutical standards for sealing and contamination prevention.The inspe -

Three-phase code is a general term for the production date, expiration date, and batch number marked on pharmaceutical packaging. It is usually presented on the surface of labels, aluminum foil, and other packaging via spraying, stamping, or laser engraving.Multiple challenges exist in inspection: C

Three-phase code is a general term for the production date, expiration date, and batch number marked on pharmaceutical packaging. It is usually presented on the surface of labels, aluminum foil, and other packaging via spraying, stamping, or laser engraving.Multiple challenges exist in inspection: C